Introduction to ADSS Fiber Optic Cables and Their Price Variations

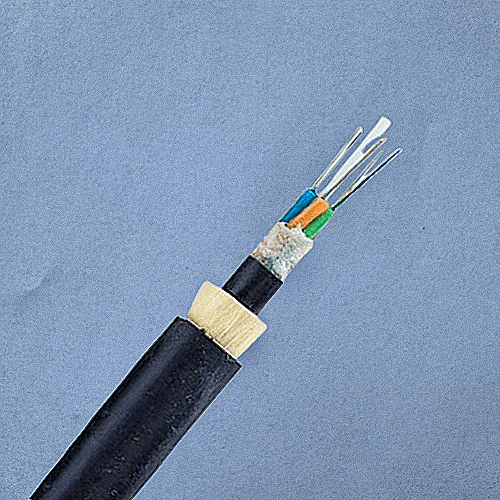

As global demand for faster and more reliable broadband expands, ADSS (All-Dielectric Self-Supporting) fiber optic cables are becoming increasingly popular for aerial installations. However, for project managers, engineers, and procurement professionals, one critical factor often influences decisions more than anything else—price.

In this article, we’ll break down the key elements that affect ADSS fiber optic cable pricing, compare typical market ranges, and help you understand how to make smart, cost-effective decisions when sourcing for telecom, power grid, or FTTH projects.

ADSS Fiber Optic Cable Price Varies Widely

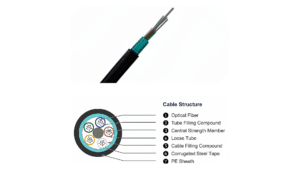

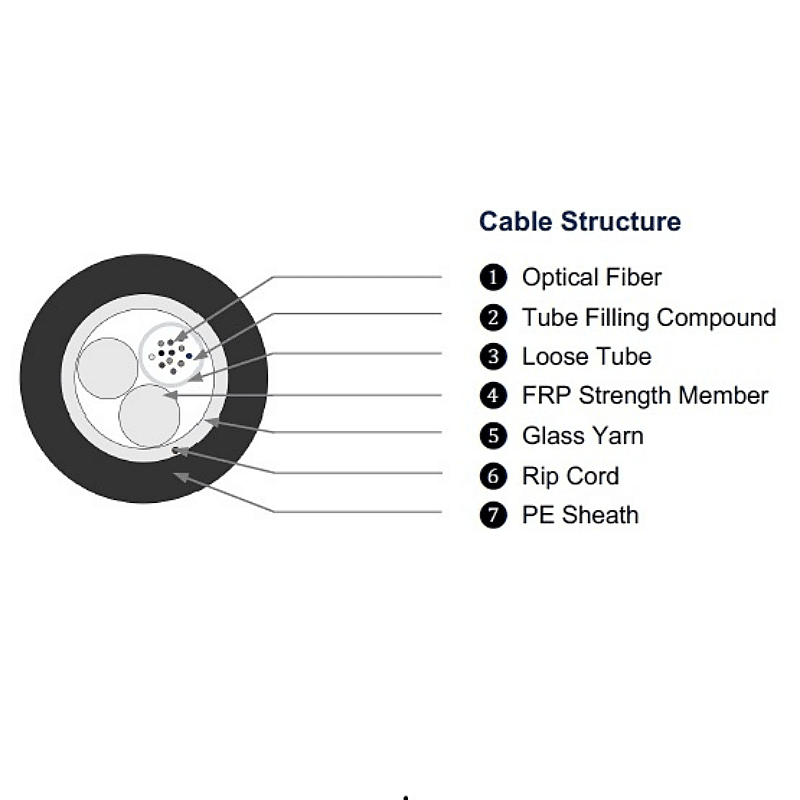

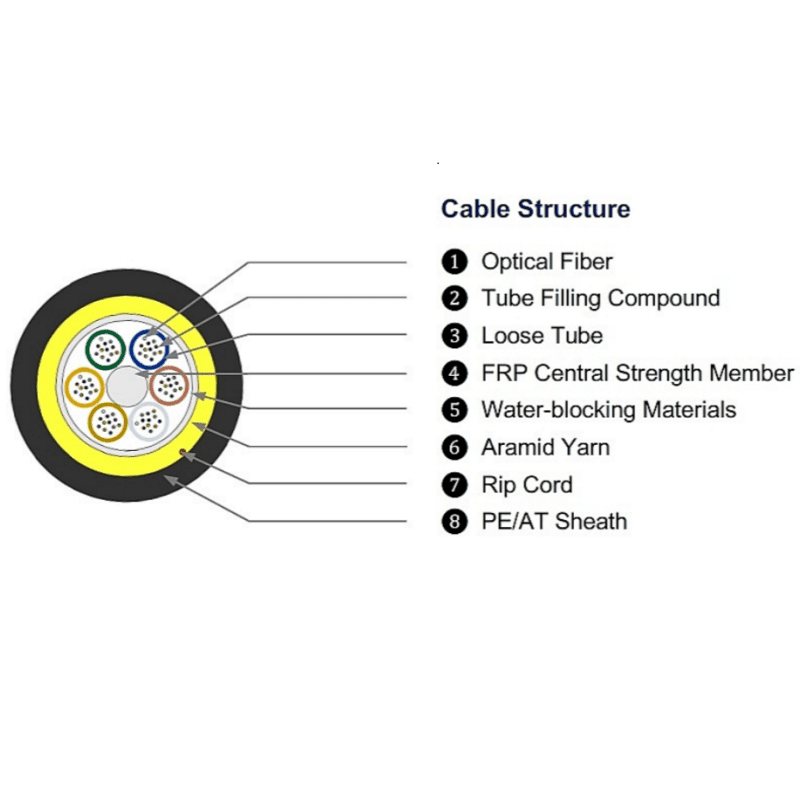

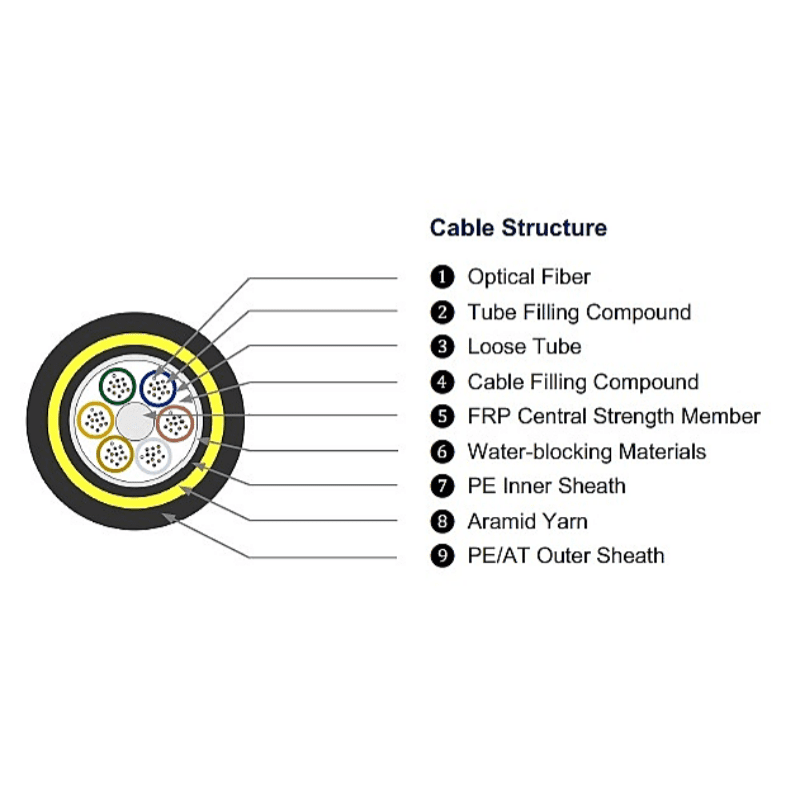

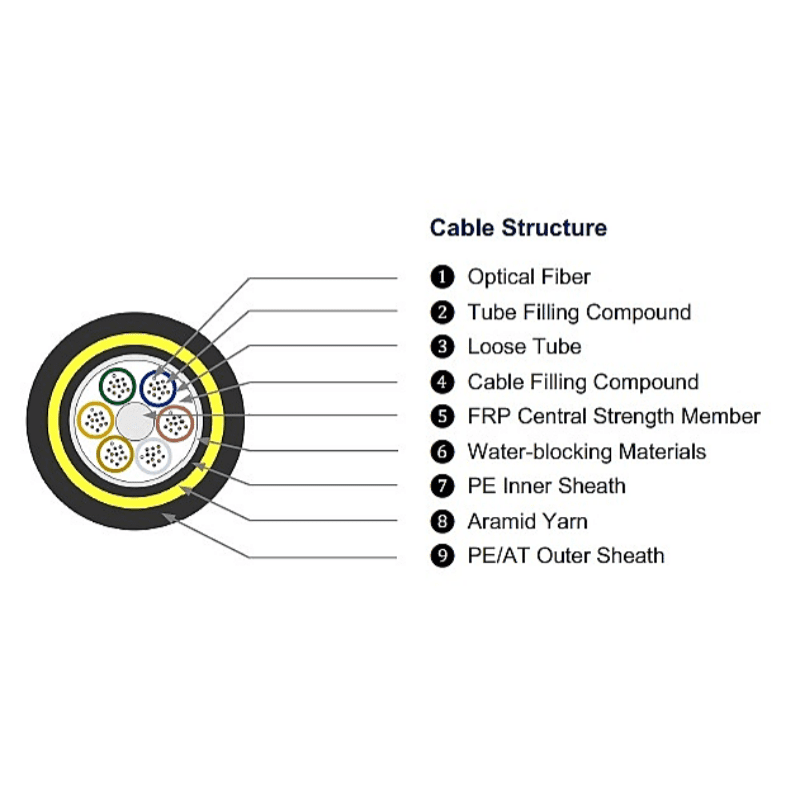

The price of ADSS (All-Dielectric Self-Supporting) fiber optic cable can vary significantly depending on the design specifications, installation environment, and span length. For example below three cable structure:

A 12-core ADSS cable for short spans (≤100 meters) might cost around $0.25–$0.35 per meter, using a standard double PE jacket and basic aramid strength members.

In contrast, a 48-core ADSS cable for long spans (≥500 meters) with high tensile strength aramid yarn, tracking-resistant outer jacket, and reinforced structure may cost $0.90–$1.20 per meter or more.

These differences arise from core count, mechanical load requirements, jacket materials (e.g., PE vs. AT), and environmental resistance. Understanding these factors is essential when budgeting for an ADSS cable project.

In power transmission projects, ADSS cable price is often compared with OPGW solutions due to differences in material cost and installation requirements.

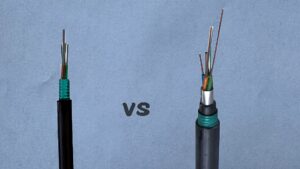

ADSS vs OPGW cable price comparison

Factors Affecting ADSS Fiber Optic Cable Price

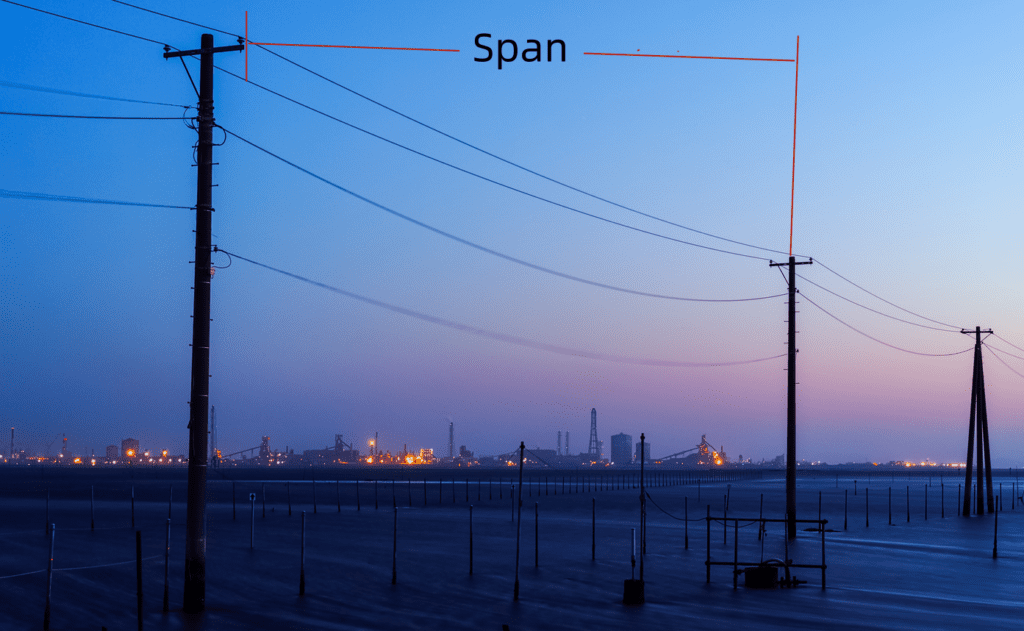

1. Cable Span Length

ADSS cable pricing is not fixed. It depends on a combination of material, structure, environmental considerations, and production scale. Here are the most important factors:

- Heavier jackets

- Thicker overall diameter

These features increase both the material cost and the manufacturing complexity, which raises the price.

2. Fiber Core Count

The number of fiber cores directly affects price:

- 2-12 cores: basic range

- 24-48 cores: medium price range

- 72-144+ cores: premium range

More fiber cores mean more buffer tubes, larger structure, and higher production cost.

3. Fiber Type and Brand

Different fiber types vary in cost:

- G.652D (standard single-mode): most affordable

- G.657A1/A2 (bend-insensitive): slightly more expensive

- G.655 (non-zero dispersion): high-performance, higher price

Also, using brand-name fiber like Corning®, YOFC®, or Fujikura® increases costs compared to generic Chinese fiber.

4. Outer Jacket Material

ADSS cable jackets are often made from:

- PE (Polyethylene): standard and cost-effective

- AT (Anti-Tracking): for high-voltage zones; more expensive

AT jackets resist electrical tracking caused by high voltage fields, especially on 66kV–220kV transmission lines.

5. Installation Environment

Custom designs are needed based on:

- Wind speed

- Ice load

- Temperature

- Electrical field exposure

Cables designed for harsh or high-voltage environments will cost more due to enhanced materials and design complexity.

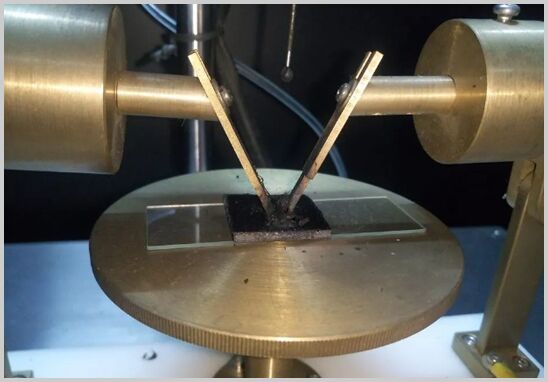

6. Certifications and Testing

Cables with international certifications like IEC, RoHS, ISO9001, or those tested to comply with ANSI/IEEE, may cost slightly more but are more trusted in international projects.

Typical ADSS Fiber Optic Cable Price Range (2025)

| Specification | Core Count | Span Length | Estimated Price (USD/km) |

| G.652D / PE Jacket | 12 cores | 100–200m | $120 – $180 |

| G.652D / AT Jacket | 24 cores | 200–400m | $180 – $250 |

| G.657A1 / PE Jacket | 48 cores | 100–200m | $200 – $280 |

| G.652D / AT Jacket | 72 cores | 300–500m | $250 – $350 |

| Corning G.655 / AT | 96–144 cores | 500m+ (high voltage) | $350 – $500+ |

How to Reduce ADSS Fiber Cable Costs

Here are five practical tips to optimize your project budget without compromising quality:

1. Order in Bulk

Larger quantities (≥20km) lead to better per-kilometer pricing due to economies of scale in manufacturing and logistics.

2. Choose Local or Regional Suppliers

If you’re sourcing from Asia (especially China), you can get competitive prices with relatively short lead times. Manufacturers often offer OEM and customized solutions without markup.

3. Evaluate Span Requirements

Avoid over-specifying the cable. If your actual span is <150m, don’t buy a design rated for 600m—it will cost more unnecessarily.

4. Use G.652D Unless Bend-Insensitive Is Required

G.657A1/A2 are great for FTTx or tight-bend scenarios, but in aerial installations, G.652D is usually enough and more affordable.

5. Negotiate Shipping and Payment Terms

Ocean freight is cheaper than air. Also, negotiating flexible payment terms can reduce your upfront capital burden.

Should You Buy ADSS Cable from China?

China is one of the world’s largest producers of ADSS fiber optic cable. Many factories offer:

- Full customization (span, core count, jacket type)

- Competitive pricing

- Fast delivery

- International certifications

But you should also verify:

- Factory background and experience

- Engineering support (especially for AT jacket designs)

- Packaging and export documentation

Look for suppliers with 10+ years of ADSS manufacturing experience, in-house testing labs, and positive customer reviews.

Conclusion

ADSS fiber optic cable is a highly efficient solution for aerial deployments—especially in telecom and power grid projects. However, its price can vary significantly depending on design, material, environment, and fiber type.

To get the best value:

- Understand your technical needs

- Don’t over-specify

- Compare multiple supplier offers

- Always verify certifications and support

Whether you are upgrading a power grid, deploying a rural broadband project, or building FTTH networks across utility poles, knowing the real ADSS cable pricing landscape can help you save thousands of dollars without compromising on quality or performance.

Need Help Finding the Right ADSS Cable at the Right Price?

Feel free to contact us for a quote or technical consultation. We offer customized ADSS cable designs for projects from 50 meters to 800 meters span, with factory-direct prices and global shipping.