Choosing the right fiber optic patch panel is a critical step in building a reliable and scalable fiber network. While patch panels may look similar at first glance, differences in structure, capacity, connector type, and application can significantly impact installation efficiency, maintenance cost, and long-term performance.

This guide walks you through the key factors to consider when selecting a fiber optic patch panel, helping network planners, engineers, and project managers make informed decisions for different deployment scenarios.

If you’re new to the topic, it’s recommended to first understand what a fiber optic patch panel is and how it works, as this article focuses on practical selection rather than basic definitions.

1. Understand Your Network Application First

The “right” patch panel always depends on where and how it will be used. Before comparing specifications, clarify your application scenario.

Common environments include:

- FTTH / FTTB access networks

- Data centers and server rooms

- Telecom central offices

- Industrial or campus networks

Each environment has different requirements for fiber density, protection level, and future expansion.

For example:

- FTTH projects often prioritize compact design and easy access

- Data centers require high-density and clean cable management

- Industrial networks may need rugged enclosures and temperature resistance

Defining the application upfront prevents over-specifying or under-specifying the product.

2. Determine Fiber Count and Port Density

One of the most common mistakes is choosing a patch panel based only on current fiber needs.

Questions to ask:

- How many fibers are required today?

- Will the network expand in the next 3–5 years?

- Is space in the rack or cabinet limited?

Practical advice:

- Choose a panel that supports moderate expansion, not just the exact fiber count

- High-density panels (LC or MPO-based) help save rack space

- Avoid filling a panel to 100% capacity on day one

A slightly larger patch panel often costs less than future reinstallation.

3. Choose the Right Mounting Type

Fiber optic patch panels are commonly available in rack-mount and wall-mount designs.

Rack-Mount Patch Panels

- Installed in 19-inch racks

- Suitable for data centers and telecom rooms

- Available in 1U, 2U, or higher configurations

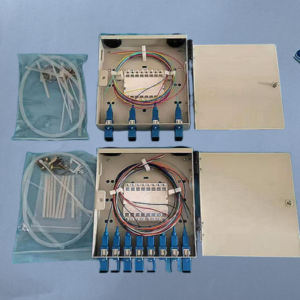

Wall-Mount Patch Panels

- Compact and space-saving

- Ideal for access networks and small equipment rooms

- Easier installation in FTTH distribution points

If you are comparing different structural options, understanding the differences between rack mount and wall mount fiber patch panels can help narrow down the best fit.

4. Select the Appropriate Connector Type

Connector type directly affects port density, compatibility, and handling convenience.

Common options include:

- LC – High density, widely used in modern networks

- SC – Durable, easy to handle, commonly used in FTTH

- FC / ST – Used in specific or legacy systems

- MPO / MTP – High-density backbone connections

Key considerations:

- Match connectors with existing equipment

- Consider technician familiarity

- Balance density and ease of maintenance

Mixing connector types without planning often leads to higher operational complexity.

5. Decide Between Splicing and Pre-Terminated Panels

Patch panels can support different termination methods.

Splice-Based Patch Panels

- Fibers are fusion spliced to pigtails

- Lower insertion loss

- Ideal for permanent installations

Pre-Terminated Patch Panels

- Faster installation

- Reduced on-site labor

- Slightly higher upfront cost

For large-scale or time-sensitive projects, pre-terminated solutions can significantly reduce deployment time.

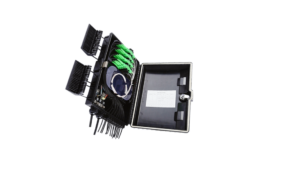

6. Evaluate Cable Management and Protection Features

A good patch panel does more than just hold adapters.

Look for features such as:

- Proper fiber bend radius control

- Clear fiber routing paths

- Secure cable fixation and strain relief

- Slide-out or hinged trays for easy access

- Labeling areas for ports and fibers

These details directly affect maintenance efficiency and network reliability, especially in high-density environments.

7. Consider Installation Environment (Indoor vs Outdoor)

Not all patch panels are designed for the same conditions.

Indoor environments:

- Data centers

- Equipment rooms

- Telecom racks

Outdoor or harsh environments:

- Street cabinets

- Base stations

- Industrial sites

Outdoor patch panels typically require:

- Weatherproof enclosures

- UV-resistant materials

- Dust and moisture protection

Using an indoor panel outdoors often leads to premature failure.

8. Think About Long-Term Maintenance and Access

Patch panels are frequently accessed during:

- Network expansion

- Equipment replacement

- Troubleshooting and testing

Choose a design that allows:

- Easy front access

- Minimal disturbance to existing fibers

- Clear visual identification of ports

Maintenance-friendly design reduces downtime and human error over the network’s lifetime.

9. Match the Patch Panel with the Overall Network Design

A patch panel should not be selected in isolation. It must align with:

- Cable types (single-mode or multi-mode)

- Network topology

- Equipment interfaces

- Future upgrade plans

In structured cabling systems, consistency across patch panels simplifies documentation and operations.

10. Choose a Reliable Manufacturer or Supplier

Finally, product quality and consistency depend heavily on the manufacturer.

When evaluating suppliers, consider:

- Experience in fiber optic manufacturing

- Compliance with international standards

- Quality control processes

- Technical support capabilities

A well-made patch panel protects your fiber investment and reduces long-term operational risk.

Final Thoughts

Choosing the right fiber optic patch panel is not about picking the most expensive or the most compact option. It’s about matching the panel to your network’s application, scale, and future growth.

By considering fiber count, connector type, mounting method, installation environment, and maintenance needs, you can select a patch panel that supports stable operation and efficient expansion for years to come.

When integrated into a well-planned fiber management system, the right patch panel becomes a foundation for network reliability rather than a future bottleneck.