Introduction

FTTH (Fiber to the Home) networks require a deployment method that is scalable, fast, and cost-efficient, especially in urban areas where demand grows gradually. Air blown fiber cable has become a preferred solution for FTTH operators due to its modular design and minimal installation disruption.

This article explains how air blown fiber cable is applied in FTTH networks and why it is ideal for last-mile and access-level fiber deployment.

Why Air Blown Fiber Is Ideal for FTTH Networks

FTTH rollouts are rarely completed in a single phase. Subscriber growth, budget planning, and local regulations often require step-by-step network expansion.

Air blown fiber systems support this model by allowing operators to:

- Install microduct infrastructure once

- Add fiber cables only when new users are connected

- Upgrade capacity without civil rework

This makes air blown fiber a future-ready solution for FTTH.

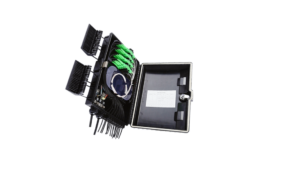

Typical FTTH Network Architecture Using Air Blown Fiber

A standard FTTH network can be divided into three layers:

1. Feeder Network (Central Office to Distribution Point)

This layer connects the central office to cabinets or fiber distribution hubs. Higher fiber counts and longer blowing distances are required.

In the feeder network connecting the central office to distribution points, higher fiber counts and longer blowing distances are required, making 24–288 cores air blown fiber cables a common choice.

2. Distribution Network (Street to Building)

From street cabinets to buildings or floors, medium fiber counts with stable blowing performance are preferred.

For distribution routes from street cabinets to buildings or floors, operators typically deploy Super Mini Uni-tube air blown fiber cables to balance fiber capacity and blowing performance.

Their structural design and installation advantages are explained in detail in our guide on Super Mini Uni-tube air blown fiber cable design and applications.

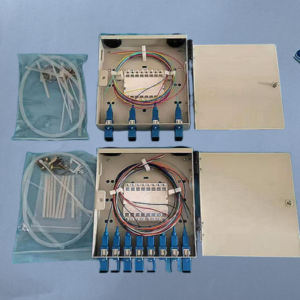

3. Drop Network (Building to Home)

The final connection to individual users requires lightweight, flexible fiber units that can be installed quickly.

The final connection from the building to individual homes requires a lightweight and flexible solution, where EPFU air blown fiber cable is widely used for FTTH drop deployment.

To better understand its structure, blowing performance, and typical FTTH use cases, you can learn more about EPFU air blown fiber cable in our dedicated article.

Advantages of Using Air Blown Fiber in FTTH Deployment

Scalable Expansion

Fibers can be added on demand as new subscribers are connected, avoiding unnecessary upfront investment.

Faster Installation

Blowing fiber through microducts is faster than traditional pulling, reducing installation time and labor costs.

Minimal Disruption

No repeated trenching or excavation is required once ducts are installed — critical for residential areas.

Easy Maintenance and Upgrades

Damaged or outdated fiber cables can be replaced without affecting existing connections.

Air Blown Fiber vs Traditional Pulled Fiber in FTTH

Compared to traditional pulled fiber cables, air blown fiber offers:

- Better flexibility for phased FTTH rollouts

- Lower initial CAPEX

- Easier capacity upgrades

Compared with conventional deployment methods, air blown fiber provides greater flexibility for FTTH rollouts, as discussed in our comparison of air blown fiber vs traditional pulled fiber cable.

How to Select the Right Air Blown Cable for FTTH

Choosing the correct cable depends on:

- Fiber count per network layer

- Blowing distance

- Microduct size

- Long-term expansion plan

To ensure stable performance and long-term scalability in FTTH projects, it is essential to choose the right air blown fiber cable based on network layer and deployment requirements.

Conclusion

Air blown fiber cable provides FTTH network operators with a flexible, scalable, and cost-effective deployment model. By combining EPFU for last-mile access, Super Mini Uni-tube for distribution, and multi-core air blown cables for feeder networks, FTTH systems can be built to grow with demand.

For modern FTTH projects, air blown fiber is not just an installation method — it is a strategic infrastructure choice.