Why Choose Armored Over Standard Patch Cables?

Traditional fiber patch cords are reliable—but fragile. A single accidental step, rodent bite, or crushed bend can cause performance degradation or total failure.

Armored patch cords solve this issue by adding a protective layer (usually steel or aluminum spiral tubing) between the fiber and the outer jacket. Think of it like a knight’s armor: the core remains the same, but it’s shielded against outside threats.

This type of cable is especially beneficial when:

- Rodents or heavy machinery may be present

- The fiber will be routed on the floor or through sharp-edged trays

- Installed in public, semi-controlled, or outdoor environments

What Makes an Armored Patch Cable Unique?

A Internal Construction

A typical armored fiber optic patch cable includes:

- Optical fiber core: Singlemode (OS2) or multimode (OM1/OM3/OM4/OM5)

- Tight buffer and strength members: Often aramid yarn (Kevlar) to absorb tension

- Metallic armor: Interlocking stainless steel or aluminum

- Outer jacket: Flame-retardant LSZH or PE, depending on indoor/outdoor use

- Connectors: LC, SC, FC, ST, with UPC or APC polish

Pro tip: Armored doesn’t mean bulky. Modern armored cables often have the same outer diameter as non-armored ones thanks to compact design.

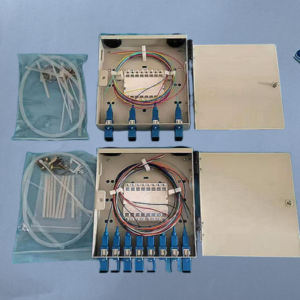

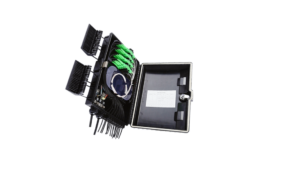

Ours Armored fiber products

Key Benefits: Real-World Use Cases

1. Increased Mechanical Strength

Armored patch cables are crush-resistant and can withstand accidental pressure (foot traffic, dropped tools, etc.). This makes them ideal for temporary runs on data center floors.

2. Rodent and Chewing Resistance

Rats, squirrels, and other pests love chewing on cables. An armored cable acts as a bite-proof barrier—especially important in basements, tunnels, and outdoor sites.

3. Faster Deployment in Harsh Locations

They can be deployed without conduits or cable trays, cutting down on infrastructure costs and labor time.

4. Reduced Downtime

Each repair or replacement costs time and money. Armored cables provide peace of mind for mission-critical systems like hospitals or financial centers.

5. Indoor-Outdoor Versatility

While traditional patch cables are limited to controlled environments, armored ones can bridge indoor and outdoor applications (when paired with weather-rated jackets).

Common Misconceptions (And the Truth)

| Myth | Reality |

| “Armored means stiff and hard to bend.” | Modern interlocking armor designs maintain high flexibility. |

| “They are too expensive.” | While the upfront cost is higher, long-term maintenance and replacement savings are significant. |

| “Only needed for military or outdoor use.” | Many enterprises now use them even inside racks and conduits for peace of mind. |

Choosing the Right Armored Patch Cable

When selecting an armored patch cable, consider the following:

A. Fiber Type

- Singlemode (OS2): Long-distance, high bandwidth; usually yellow jackets.

- Multimode (OM3/OM4/OM5): Shorter distances, lower cost; aqua or lime jackets.

B. Connector Type

- Choose the right end-to-end combination (LC-LC, SC-SC, LC-SC, etc.) depending on your equipment.

C. Armor Type

- Spiral steel armor: Flexible, ideal for indoor use.

- Corrugated steel or aluminum tape: Tougher, designed for direct burial or rodent protection.

D. Jacket Material

- LSZH: Low-smoke, halogen-free for indoor safety compliance.

- PE or TPU: UV-resistant for outdoor environments.

E. Fire Rating

Required in buildings. Choose OFNR, OFNP, or equivalent according to your country’s regulations.

Side-by-Side: Armored vs Non-Armored

| Feature | Non-Armored Cable | Armored Cable |

| Cost | Lower | Higher |

| Durability | Basic | High |

| Installation Flexibility | Needs protection | Can be laid directly |

| Crush Resistance | Low | Excellent |

| Rodent Protection | None | Yes |

| Maintenance Frequency | Higher | Lower |

Verdict: If your cable is at risk of being touched, crushed, or chewed—armored wins.

Where Armored Patch Cables Are Used

- Data Centers: Under raised floors, high-density switch zones

- Telecom and ISP Networks: Last-mile access points or roadside cabinets

- Smart Buildings: From core to floor, where tight bends and mixed environments exist

- Factories and Plants: Oil, gas, automotive, steel—environments where EMI, mechanical stress, and chemicals are a factor

- Tunnels and Transit: Rodent-heavy, unmonitored environments

Case Study: Armored Cables in a Logistics Warehouse

A large warehouse in Southeast Asia implemented a fiber backbone to connect its automation systems and security network. After replacing standard patch cables (which frequently got crushed or chewed) with armored patch cords:

- Breakage incidents dropped by 93%

- Downtime reduced by over 70 hours per year

- ROI achieved within 6 months

Emerging Trends

- Micro-Armored Cables: Thinner but equally protective—perfect for high-density racks

- Plug-and-Play Armored Solutions: Pre-terminated and tested, ready to deploy

- Hybrid Fiber Cables: Combining power and signal in one armored sheath

- Color-Coded Armoring: For fast identification of SM/MM, duplex/simplex in the field

Installation Tips from the Field

- Don’t bend it like copper. Follow the specified bend radius (usually ~10× the outer diameter).

- Secure the cable properly using brackets or cable glands—metal armor adds weight.

- Clean connectors before insertion—the armor doesn’t protect the ferrule tip.

- Avoid over-tightening—armor helps, but crushing still possible with clamps or zip ties.

- Use test reports—good suppliers provide insertion loss and return loss data for each cord.

Maintenance & Inspection

Armored cables require less frequent checks, but don’t ignore them entirely:

- Watch for jacket cracking, especially near connectors.

- Clean and inspect connectors periodically.

- Store them coiled loosely, not kinked or forced.

Final Thoughts

Armored fiber optic patch cables are no longer a niche solution. From corporate campuses to manufacturing plants, they are fast becoming a standard for reliability-first installations. While the initial investment is slightly higher, the total lifecycle cost is often lower thanks to improved protection, fewer outages, and reduced maintenance.

If you’re managing fiber in any environment outside a fully controlled cabinet—you owe it to yourself and your network to consider armored patch cords.