When sourcing armored fiber optic cable for outdoor or industrial projects, buyers often face a critical decision: purchase from a local distributor or buy directly from a China-based manufacturer. While both options deliver compliant products, the final cost structure can differ dramatically.

Understanding where those differences come from helps you avoid overpaying—or underestimating hidden expenses.

Understanding the Two Supply Models

Buying from a Local Supplier

Local suppliers typically stock standard armored fiber optic cable types and provide fast delivery. Their pricing usually includes warehousing, local certification, and after-sales handling.

However, many buyers don’t realize that local pricing already includes multiple layers of markup, often based on imported inventory originally sourced overseas.

Buying Directly from a China Manufacturer

China manufacturers produce armored fiber optic cables at scale, offering factory-direct pricing with flexible specifications. Many international buyers choose this route when optimizing long-term project costs.

If you want a broader view of how armored cable prices are structured across specifications, you can refer to our armored fiber optic cable pricing overview, which explains base cost drivers in detail.

Price Comparison: China vs Local Market

| Cost Element | China Manufacturer (FOB) | Local Supplier |

|---|---|---|

| Base cable price | Low | High |

| Customization | Flexible, low cost | Limited or expensive |

| Minimum order | 1–2 km typical | Often per reel |

| Lead time | 7–15 days production | Immediate stock |

| Markup layers | None | Distributor + reseller |

In real-world projects, direct factory sourcing often reduces cable cost by 30–60%, especially for multi-kilometer deployments.

Where Local Suppliers Still Make Sense

Local sourcing can be cost-effective when:

- Project quantities are very small

- Installation timelines are extremely tight

- Regulatory approval requires local certification only

For example, projects involving direct burial installations may benefit from nearby stock when timelines are critical. Cost considerations for such environments are explained in our guide on underground armored fiber cable cost factors.

Hidden Costs When Buying from China

Lower unit prices do not automatically mean lower total cost. Buyers should account for:

- International freight (sea vs air)

- Import duties and VAT

- Customs clearance

- Insurance and port charges

To avoid surprises, many buyers calculate the full landed cost before deciding. A step-by-step method is outlined in how to estimate the full landed cost of armored fiber cable imports.

Product-Level Cost Differences

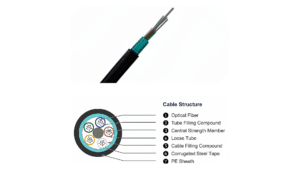

Not all armored cables benefit equally from factory sourcing. Complex constructions—such as steel tape armored outdoor fiber optic cable—show greater savings when ordered directly due to reduced handling and customization flexibility.

You can review specifications and structure details on our steel tape armored outdoor fiber optic cable to see where factory pricing creates the biggest advantage.

Quality & Compliance: Is Cheaper Riskier?

Modern Chinese manufacturers typically provide:

- Full attenuation and tensile test reports

- IEC / ISO / RoHS compliance

- Factory QA documentation

The key difference lies not in product quality, but in how much of the supply chain margin you are paying for convenience.

Final Verdict: Which Option Is More Cost-Effective?

| Buyer Type | Better Choice |

|---|---|

| Large projects (>5 km) | China manufacturer |

| OEM / customized specs | China manufacturer |

| Emergency replacement | Local supplier |

| Long-term procurement | China manufacturer |

For most contractors, system integrators, and telecom projects, factory-direct sourcing delivers better long-term value, provided logistics are planned correctly.