Introduction

A fiber optic termination box is a core component in modern fiber optic networks, providing a secure and organized point for fiber termination, splicing, and distribution. It is widely deployed in FTTH, FTTB, and other access networks to ensure stable signal transmission from backbone cables to end users.

In real projects, engineers often hesitate between several types of fiber enclosures at the access layer. A common question is whether a termination box or a fiber distribution box is more suitable for a given scenario. This confusion usually comes from overlapping functions in small- to medium-scale FTTH deployments, where both boxes may appear similar at first glance.

This guide explains what a fiber optic termination box is, how it works in practice, where it is typically installed, and how to choose the right model for different network environments.

What Is a Fiber Optic Termination Box?

A fiber optic termination box is an enclosure designed to terminate incoming optical fiber cables and distribute optical signals to drop cables or patch cords. It integrates fiber splicing, adapter management, and cable protection in one compact unit.

In FTTH access networks, this type of enclosure is commonly referred to as an FTTH termination box and is usually installed close to the end user, such as inside apartments, corridors, or building distribution areas. At this point in the network, the box serves as the interface between feeder fibers and subscriber drop cables, making access, testing, and maintenance much easier.

Key Functions of a Fiber Optic Termination Box

- Fiber termination: Provides a stable endpoint for optical fibers

- Splicing & protection: Protects fusion or mechanical splices inside dedicated trays

- Fiber management: Maintains proper bend radius and organized routing

- Distribution: Routes optical signals to end users or downstream equipment

- Network protection: Shields fibers from dust, moisture, and mechanical damage

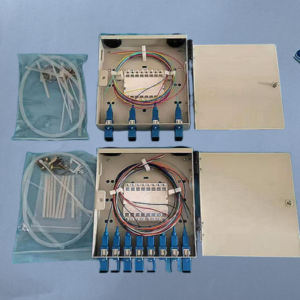

Structure & Main Components

A typical fiber optic termination box consists of several functional parts working together to protect and manage fibers.

Enclosure

The enclosure is usually made of ABS, PC, or metal materials, offering mechanical strength and environmental protection. Indoor models focus on compact size and appearance, while outdoor models emphasize sealing and durability.

Splice Tray

Splice trays are designed to hold and protect fusion splices, preventing stress and accidental bending. Stackable tray designs allow higher fiber capacity when needed.

Adapter Panel

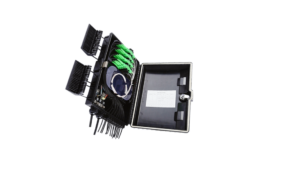

The adapter panel supports SC, LC, FC, or ST adapters for connecting patch cords or drop cables. In some FTTH applications, the internal layout is designed with enough space and routing flexibility to accommodate PLC splitters. This allows optical signals to be divided directly inside the termination box, reducing the need for additional distribution enclosures and simplifying network topology.

Cable Entry & Fixing System & Fixing System

Cable entry ports, sealing grommets, and strain relief components ensure that incoming and outgoing cables are fixed securely while maintaining environmental protection.

Types of Fiber Optic Termination Boxes

Indoor and Outdoor Termination Boxes

Fiber optic termination boxes are mainly classified by installation environment. The correct choice depends on exposure to dust, moisture, sunlight, and mechanical stress.

Selecting the right termination box largely depends on environmental conditions. Boxes installed inside buildings usually prioritize compact size and clean appearance, while those exposed to outdoor conditions must withstand moisture, dust, and sunlight. Understanding these differences early helps avoid premature failure and unnecessary replacement during later stages of the project.

Indoor models are typically used in homes, offices, and corridors, while outdoor models are designed for walls, poles, and street-side installations. in homes, offices, and corridors, while outdoor models are designed for walls, poles, and street-side installations.

Termination Box Capacity

Termination boxes are available in multiple fiber capacities, commonly including 2, 4, 8, 12, and 24 cores. Choosing the right capacity is not only about current demand but also about future expansion.

In many projects, incorrect sizing leads to early replacement. In many projects, incorrect sizing leads to early replacement or complex rework. Planning capacity based only on current demand often leaves no room for future subscribers or service upgrades. A clear understanding of how fiber capacity scales from small 2-core boxes to larger 24-core designs helps balance initial investment with long-term flexibility.

Applications

Fiber optic termination boxes are widely used across access and distribution networks:

- FTTH and FTTB access networks

- Residential buildings and villas

- Commercial offices and data rooms

- Outdoor telecom cabinets and distribution points

In multi-dwelling deployments, especially apartment buildings and MDU projects, termination boxes provide an organized interface between feeder cables and individual drop cables.

How to Choose the Right Fiber Optic Termination Box

Selecting the correct fiber optic termination box requires balancing technical requirements and installation conditions.

Key factors include:

- Required fiber count and expansion margin

- Indoor or outdoor installation environment

- Adapter type (SC/APC, SC/UPC, LC, etc.)

- Cable type (drop cable, indoor cable, armored cable)

- Required protection level (IP rating)

Capacity planning is often underestimated during early design stages. Choosing the correct termination box capacity (2–24 cores) can significantly reduce future rework and service interruption.

Installation & Maintenance Tips

Even a high-quality termination box may fail to perform as expected if installation is not done correctly.

Improper cable fixing, excessive bending, or poor sealing are common issues. Many performance issues observed after network handover can be traced back to installation quality rather than product design. Problems such as excessive bending, poor strain relief, or improper sealing may not be immediately visible but can affect long-term reliability. Paying attention to correct installation procedures is therefore just as important as choosing the right termination box model.

General best practices include:

- Proper cable stripping and cleaning

- Maintaining minimum bend radius

- Securing cables with strain relief

- Clear labeling for maintenance

- Periodic inspection of outdoor boxes

Advantages of High-Quality Fiber Optic Termination Boxes

- Improved network stability and optical performance

- Easier installation and maintenance

- Reduced risk of fiber damage

- Long service life in indoor and outdoor environments

- Scalable design for future network growth

FAQs About Fiber Optic Termination Boxes

What is the difference between a fiber termination box and a fiber distribution box?

This is one of the most common questions in access network design.

Can fiber optic termination boxes be used outdoors?

Yes. Outdoor models are specifically designed with sealed structures and UV-resistant materials.

How many fibers can a termination box support?

Most standard models support between 2 and 24 cores, depending on internal layout and splice tray design.

What problems are commonly found in termination boxes?

Many issues encountered on site are preventable. Most problems found in the field are not caused by the termination box itself but by environmental exposure or installation details. Issues such as moisture ingress, connector contamination, or accidental fiber stress tend to appear over time if preventive measures are ignored.

Conclusion

Although small in size, the fiber optic termination box plays a critical role in access network reliability and maintainability. By understanding its structure, types, applications, and installation requirements, network designers and installers can significantly improve project outcomes.

As a professional fiber optic manufacturer with more than 20 years of experience, we offer a complete range of indoor and outdoor fiber optic termination boxes for FTTH and access network projects.