Installing a fiber optic patch panel may seem straightforward, but many network issues originate from small installation mistakes. Poor fiber routing, incorrect bend radius, or improper labeling can all lead to signal loss, maintenance difficulties, and unexpected downtime.

This article highlights the most common fiber patch panel installation mistakes, explains why they cause problems, and provides practical guidance on how to avoid them.

If you need a foundational understanding of fiber patch panels, start with our pillar article:

What Is a Fiber Optic Patch Panel and How Does It Work?

Ignoring Minimum Bend Radius Requirements

The Mistake

Fibers are bent too tightly inside the patch panel or cable management tray.

Why It’s a Problem

Exceeding the minimum bend radius increases attenuation and may cause long-term fiber damage.

How to Avoid It

- Follow manufacturer bend radius guidelines

- Use proper fiber routing paths and management rings

- Avoid sharp corners and forced bends

Poor Fiber Cable Management

The Mistake

Loose fibers, tangled patch cords, or overcrowded panels.

Why It’s a Problem

Poor cable management makes troubleshooting difficult and increases the risk of accidental disconnections.

How to Avoid It

- Route fibers neatly and consistently

- Use cable managers, guides, and tie points

- Leave service loops for future maintenance

Incorrect Fiber Polarity

The Mistake

Transmit (Tx) and receive (Rx) fibers are connected incorrectly.

Why It’s a Problem

Incorrect polarity results in link failures or intermittent connectivity issues.

How to Avoid It

- Follow standardized polarity methods

- Verify polarity during installation

- Test links before commissioning

Insufficient Labeling and Documentation

The Mistake

Ports and fibers are unlabeled or labeled inconsistently.

Why It’s a Problem

Technicians cannot quickly identify connections, leading to errors during maintenance or upgrades.

How to Avoid It

- Clearly label ports, cables, and trays

- Use durable, readable labels

- Keep installation records and diagrams updated

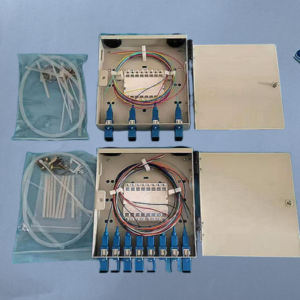

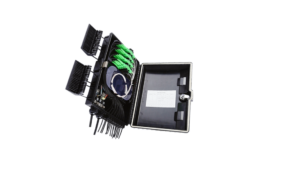

Using the Wrong Patch Panel Type

The Mistake

Selecting a patch panel that does not match the installation environment or network scale.

Why It’s a Problem

Improper panel selection can cause overcrowding, poor protection, or limited expansion.

How to Avoid It

- Choose between rack mount, wall mount, indoor, or outdoor panels based on application

- Plan capacity for future growth

- Match panel specifications to network requirements

Inadequate Fiber Protection at Cable Entry Points

The Mistake

Cables enter the patch panel without proper strain relief or protection.

Why It’s a Problem

Mechanical stress can damage fibers and connectors over time.

How to Avoid It

- Use proper strain relief devices

- Secure incoming cables

- Protect fibers from sharp edges

Skipping Testing After Installation

The Mistake

Assuming the installation is correct without testing.

Why It’s a Problem

Hidden issues may not appear until the network is live, making troubleshooting more disruptive.

How to Avoid It

- Perform continuity and loss testing

- Verify each connection

- Document test results for future reference

Overlooking Future Maintenance and Expansion

The Mistake

Installing the patch panel without considering future changes.

Why It’s a Problem

Lack of planning can lead to rework, downtime, and inefficient upgrades.

How to Avoid It

- Leave spare ports and space

- Use modular patch panels where possible

- Design for scalability

Not Following Manufacturer Guidelines

The Mistake

Ignoring installation instructions or best practices provided by the manufacturer.

Why It’s a Problem

Incorrect installation may void warranties or reduce product lifespan.

How to Avoid It

- Review installation manuals

- Follow recommended torque, routing, and mounting instructions

- Use approved accessories

Treating Patch Panel Installation as a One-Time Task

The Mistake

Failing to maintain and review the installation over time.

Why It’s a Problem

Network conditions change, and unmanaged patch panels degrade in performance and usability.

How to Avoid It

- Periodically inspect patch panels

- Update labels and documentation

- Maintain consistent fiber management practices

Conclusion

Most fiber patch panel problems are not caused by defective components but by installation and maintenance mistakes. By understanding common errors and following proven best practices, network engineers can improve reliability, reduce downtime, and simplify long-term operation.

A well-installed fiber patch panel is not just a termination point—it is a foundation for a stable and scalable fiber network.