Introduction

In Fiber-to-the-Home (FTTH) networks, optical splitters play a crucial role in dividing a single optical signal into multiple paths for distribution to end users. Among different types of splitters, planar lightwave circuit (PLC) splitters are widely used because of their low insertion loss, uniform splitting performance, and high reliability.

As FTTH deployments grow, engineers are increasingly interested in how PLC splitter integration affects fiber termination point design—especially when splitters are placed inside or adjacent to termination boxes. This article explains how PLC splitters work in fiber optic termination boxes, what design challenges they introduce, and how to make deployment decisions that balance performance and practicality.

What Is a PLC Splitter in FTTH Networks?

A PLC splitter is an optical device that evenly divides an input signal into multiple outputs, making it ideal for Passive Optical Network (PON) architectures. Unlike larger mechanical splitters or cascaded splitters, PLC splitters provide consistent performance across ports and are compact enough to fit into controlled enclosures.

When placed near the subscriber side, PLC splitters can reduce the amount of fiber cabling required for distribution and simplify the access network layout. Many engineers refer to this as optimal splitter placement for FTTH termination points, since locating the splitter appropriately improves signal balance and reduces redundant cabling.

Why Integrate Splitters into Termination Boxes?

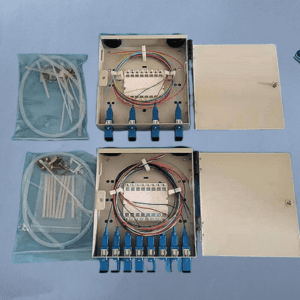

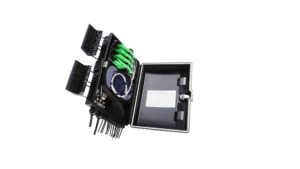

Integrating splitters into FTTH termination boxes can make installations cleaner and more modular. When a PLC splitter is accommodated inside the box, the termination point becomes both a distribution and connection hub, minimizing the need for extra external housings or additional cabinets.

From a design perspective, this approach helps support compact fiber distribution at the subscriber edge, where space is limited and cable routing can be complex. Technicians appreciate this layout because it reduces field errors and streamlines testing procedures.

Design Considerations for Splitter-Ready Termination Boxes

When choosing a termination box that will house a PLC splitter, several factors must be evaluated:

1. Internal Space and Tray Layout

Splitters and pigtails need secure placement within the box without causing excessive fiber bending. Ensuring adequate internal routing for splitter pigtails helps preserve fiber performance and reduces loss in critical sections.

2. Bend Radius and Routing Guides

Maintaining minimum bend radius for both splitter fibers and drop cables is essential to prevent micro bending loss. Designers usually assess how bend radius protection guides in termination boxes affect fiber longevity.

3. Environmental Protection

In outdoor or semi-outdoor installations, enclosures must provide proper sealing and protection against dust, moisture, and UV exposure. These conditions especially affect splitter performance over time, which is why installers consider outdoor robustness for splitter-ready enclosures before deployment.

Scenarios Where Embedded Splitters Make Sense

Embedded PLC splitters in termination boxes are most commonly used in:

- Small-to-medium FTTH rollouts, where subscriber numbers per distribution point are limited

- Multi-dwelling units, where space is constrained and modular deployment is important

- Areas with complex cabling paths, where reducing additional junction points simplifies field work

This approach is especially useful when planning modular splitter deployment in FTTH projects, because it reduces extra junction points and keeps fiber routing more consistent across different sites.

This strategy also improves maintainability by centralizing splicing, splitter stays, and connector work in a single, well-organized enclosure.

Field Testing and Validation Tips

After installation, verifying splitter performance is critical. Field technicians use OTDR and power meter tests to confirm that each split path operates within acceptable loss limits.

When troubleshooting splitter-ready termination boxes, teams often record signal uniformity across multiple PON ports to ensure balanced distribution. Issues related to splitter placement, bending, or environmental exposure can then be isolated more quickly.

Conclusion

Integrating PLC splitters into fiber optic termination boxes offers a modular, organized way to manage signal distribution and subscriber connections in FTTH networks. By considering internal space, routing paths, environmental protection, and field testing needs, engineers can design termination points that balance performance, reliability, and ease of maintenance.