Introduction

In fiber-to-the-home (FTTH) networks, fiber optic termination boxes are essential enclosures where cables are spliced, protected, and routed toward end users. Depending on where these enclosures are placed, their design, protection level, and material requirements differ substantially. Choosing the wrong box type can lead to premature failures, increased maintenance, or poor signal reliability.

This article explains the engineering and application differences between indoor fiber termination box designs and outdoor fiber termination box solutions, helping network planners make informed decisions based on site conditions.

What Makes an Indoor Termination Box Different?

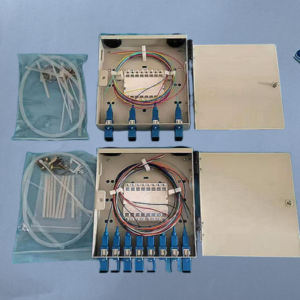

Indoor termination boxes are intended for locations that are protected from harsh weather and environmental elements. These boxes are typically installed inside homes, utility closets, data rooms, or controlled facilities where temperature, humidity, and dust levels are relatively stable. They focus on providing compact fiber management for clean interior environments with easy access for technicians.

In such settings, lightweight materials like ABS or PC can be used without adding rugged protective layers. The emphasis is placed on neat cable routing, fire safety compliance, and convenient access for maintenance without dealing with outdoor exposure challenges. Indoor boxes often feature lower protection ratings as they are not expected to withstand rain, dust storms, or UV radiation.

Why Outdoor Termination Boxes Are Built Tough

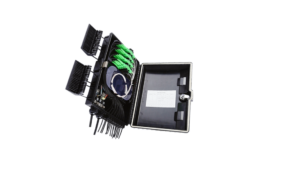

Outdoor termination boxes need to withstand a broad range of environmental stresses. Unlike indoor models, these enclosures must be resistant to moisture, temperature changes, direct sunlight, dust, and mechanical impact. Because of this, outdoor boxes are typically constructed with heavier materials and advanced sealing techniques to meet robust weatherproofing standards for outdoor fiber enclosures.

Outdoor enclosures often use IP-rated designs (such as IP55, IP65, or higher) and reinforced housing to prevent water ingress and dust accumulation, ensuring signal integrity even in adverse climates. Mounting options might include poles, building exteriors, or street-side cabinets, each requiring careful sealing and reinforcement.

Material and Protection Level Considerations

The material and protection level of a termination box can greatly impact its service life and performance. For indoor installations, boxes usually rely on lightweight plastics without extensive sealing features, prioritizing simplicity and ease of installation.

Outdoor models, however, often combine ABS or PC with additional coatings, reinforced frameworks, and rubber gaskets. These ensure long-term durability and are designed for high-impact resistance for fiber outdoor installations, protecting sensitive fiber connections from environmental degradation.

Outdoor designs may also integrate enhanced locking mechanisms to prevent tampering, which is usually unnecessary for indoor units.

Installation Site and Accessibility

Environmental conditions influence not only material choice but also the installation process. Indoor boxes are typically mounted in easily accessible locations like utility rooms, hallways, or data closets, making them suitable for environments where frequent access or maintenance is required.

By contrast, outdoor boxes are installed in exposed sites such as on poles, exterior walls, or ground-level distribution points. In these applications, engineers often assess environment-specific mounting strategies for termination enclosures to ensure both long-term stability and ease of servicing without compromising weather resistance.

Practical Deployment Scenarios

Indoor Deployment

- Residential apartments where cabinets are wall-mounted inside hallways

- Offices or business spaces with centralized communication closets

- Environments requiring fire safety ratings and easy maintenance access

Indoor boxes work well where physical conditions are controlled and no extreme weather exposure is expected.

Outdoor Deployment

- Utility poles serving neighborhood access points

- Building exteriors where fiber transitions from outside plant to indoor routing

- Outdoor cabinets in industrial or campus environments

Outdoor boxes must meet stringent environmental protection requirements to ensure reliable fiber performance in all conditions.

Summary: Choosing Between Indoor and Outdoor

Choosing the right type of termination box comes down to deployment environment, protection needs, and maintenance accessibility. Selecting an indoor model in a humid outdoor location can lead to moisture ingress and signal degradation. Conversely, using an outdoor unit indoors may increase cost and maintenance complexity without added benefit.

Understanding environmental demands for fiber termination solutions helps network planners match the right enclosure to the correct installation site, optimizing both performance and lifecycle costs.