In modern fiber optic networks, reliability, scalability, and ease of maintenance are just as important as transmission speed. Whether in data centers, FTTH deployments, telecom rooms, or industrial networks, one component quietly plays a critical role in keeping fiber connections organized and manageable: the fiber optic patch panel.

At first glance, a fiber patch panel may look like a simple metal box with adapters on the front. But behind this modest appearance lies a key element that ensures network stability, simplifies troubleshooting, and supports future expansion. In this article, we’ll explore what a fiber optic patch panel is, how it works, why it matters, and how to choose the right one for your application.

What Is a Fiber Optic Patch Panel?

A fiber optic patch panel is a hardware unit designed to terminate, organize, protect, and manage fiber optic cables. It provides a central point where incoming fiber cables can be connected to outgoing patch cords, making the network structured, accessible, and easy to maintain.

In simple terms, the patch panel acts as a bridge between permanent fiber cabling and active network equipment such as switches, OLTs, or routers.

Core Functions of a Fiber Patch Panel

- Fiber termination: Secures fiber cables through splicing or connectors

- Connection management: Routes fiber signals via adapters and patch cords

- Protection: Shields delicate fibers from bending, pulling, or contamination

- Organization: Keeps fiber paths clearly labeled and logically arranged

Without a patch panel, fiber connections would be chaotic, hard to trace, and highly vulnerable to damage.

Why Fiber Optic Patch Panels Are Essential in Networks

As fiber networks grow in size and complexity, direct cable-to-equipment connections become impractical. Patch panels solve this problem by introducing structure and flexibility.

Key Benefits

- Simplified maintenance

Technicians can reroute or replace connections without disturbing backbone cables. - Reduced downtime

Clear labeling and organized routing make fault isolation faster. - Improved scalability

New fibers can be added without redesigning the entire network. - Enhanced protection

Fibers are safely managed with proper bend radius and strain relief. - Professional network appearance

Clean layouts improve both operation efficiency and compliance standards.

In short, a fiber patch panel turns a fragile fiber network into a manageable infrastructure system.

How Does a Fiber Optic Patch Panel Work?

To understand how a fiber patch panel works, let’s follow the signal path step by step.

Step 1: Fiber Cable Entry

Incoming fiber optic cables enter the patch panel from the rear or side. These are typically trunk cables coming from outdoor networks, risers, or horizontal cabling systems.

The cable is fixed using clamps or strain relief mechanisms to prevent movement or tension on the fibers.

Step 2: Fiber Termination

Inside the patch panel, fibers are terminated in one of two ways:

- Fusion splicing: The fiber is permanently spliced to a pigtail

- Pre-terminated connectors: The fiber already has connectors installed

The terminated fibers are then routed to the front panel adapters.

Step 3: Adapter Interface

Adapters (LC, SC, FC, ST, etc.) are mounted on the front of the patch panel. These adapters act as connection ports.

Each adapter connects:

- One side → internal fiber (from the incoming cable)

- Other side → external patch cord

Step 4: Patch Cord Connection

Patch cords link the patch panel to active equipment or to another patch panel.

This modular approach allows technicians to:

- Change routes easily

- Upgrade equipment without touching backbone fibers

- Test and monitor individual links

Step 5: Signal Transmission

Once connected, optical signals pass through:

Equipment → patch cord → adapter → terminated fiber → backbone cable

The patch panel itself does not alter or amplify the signal—it simply provides a controlled, low-loss connection environment.

Common Types of Fiber Optic Patch Panels

Different network scenarios require different patch panel designs. Below are the most common types.

1. Rack-Mount Fiber Patch Panels

- Installed in standard 19-inch racks

- Common in data centers and telecom rooms

- Available in 1U, 2U, 4U configurations

Best for: High-density, centralized networks

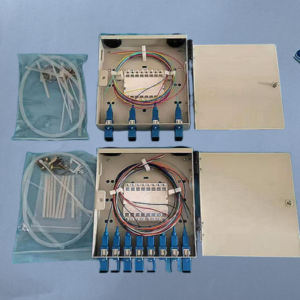

2. Wall-Mount Fiber Patch Panels

- Compact and space-saving

- Mounted on walls or cabinets

- Often used in FTTH or access networks

Best for: Small equipment rooms and distribution points

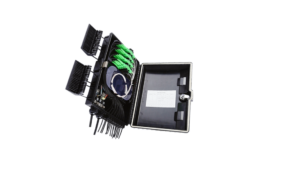

3. Outdoor Fiber Patch Panels

- Weatherproof and rugged

- UV-resistant, waterproof, dustproof

- Suitable for outdoor cabinets or base stations

Best for: Outdoor and harsh environments

4. Sliding vs Fixed Patch Panels

- Sliding panels allow easier access during maintenance

- Fixed panels offer higher stability and lower cost

Fiber Connector Types Used in Patch Panels

The performance and density of a patch panel depend heavily on connector types.

Common Connector Options

- LC – Small form factor, high density

- SC – Widely used, push-pull design

- FC – Threaded, vibration-resistant

- ST – Bayonet-style, legacy systems

- MPO/MTP – Ultra-high-density backbone connections

Choosing the right connector ensures compatibility and optimal space utilization.

Applications of Fiber Optic Patch Panels

Fiber patch panels are used across almost every fiber-based network.

Typical Applications

- Data centers

- FTTH / FTTB / FTTX networks

- Telecom central offices

- Industrial Ethernet systems

- Campus and enterprise networks

- CATV and broadcasting systems

Wherever fiber cables meet equipment, a patch panel is usually present.

How to Choose the Right Fiber Optic Patch Panel

Selecting the right patch panel is not just about size—it’s about long-term efficiency.

Key Selection Factors

- Fiber count and density requirements

- Connector type compatibility

- Installation environment (indoor or outdoor)

- Splicing or pre-terminated design

- Future expansion plans

- Compliance with international standards

A well-chosen patch panel reduces maintenance costs and supports network growth.

Best Practices for Using Fiber Patch Panels

To maximize performance and lifespan, consider the following best practices:

- Maintain proper bend radius

- Use clear fiber labeling

- Keep dust caps on unused adapters

- Avoid over-tightening cable ties

- Regularly inspect and clean connectors

Good management habits are just as important as good hardware.

Fiber Optic Patch Panel vs Fiber Distribution Frame (FDF)

While often confused, these two serve different roles:

| Feature | Patch Panel | FDF |

| Size | Compact | Larger |

| Function | Connection & management | Central fiber distribution |

| Use Case | Equipment-level | Network core |

Patch panels are typically part of a larger fiber management system.

Final Thoughts

A fiber optic patch panel may not be the most eye-catching component in a fiber network, but it is one of the most important. It brings order to complexity, protects valuable fiber assets, and provides the flexibility needed in modern high-speed networks.

As fiber deployments continue to expand—driven by FTTH, data centers, and industrial networking—the role of well-designed patch panels becomes even more critical. Investing in the right fiber optic patch panel today means lower maintenance costs, higher reliability, and smoother network expansion tomorrow.

If you view fiber infrastructure as a long-term asset rather than a short-term installation, a quality patch panel is not optional—it’s essential.