This guide provides a complete overview of air blown fiber cable technology, including working principles, cable types, selection guidelines, applications, and future scalability.

Air blown fiber cable Introduction

As fiber optic networks rapidly expand to meet growing demands in broadband, smart cities, and enterprise connectivity, the need for scalable and cost-effective deployment solutions becomes urgent. Air blown fiber optic cable, also known as ABF (Air Blown Fiber), has become a strategic technology for network builders who seek flexibility, speed, and minimal disruption during expansion.

Unlike conventional fiber installations, air blown systems allow for fiber cables to be installed on demand through microducts using compressed air. This modular approach reduces initial investment, enables pay-as-you-grow deployment, and is particularly suitable for FTTH (Fiber to the Home), FTTB, metro networks, campuses, and data centers.

Three air blown fiber cable type

In this article, we’ll explore the working principle of air blown fiber, its benefits, common applications, and the main types of air blown cables we offer — including EPFU, Super Mini Uni-tube Air Blown Cable, and 24–288 Cores Air Blown Cable.

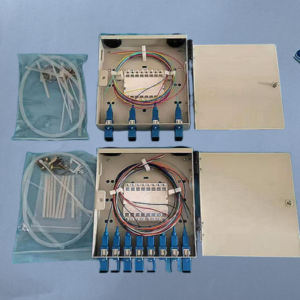

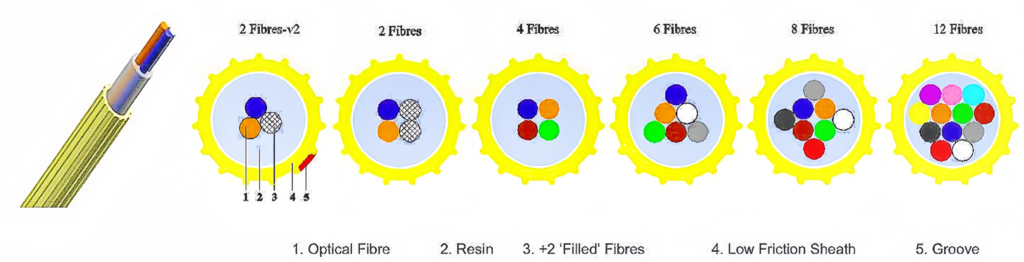

EPFU air blown fiber cable structure

The EPFU air blown fiber cable is an ultra-lightweight, miniaturized cable designed for microduct installation using air blowing techniques. It features a simple and compact structure optimized for high-performance fiber deployment in FTTx and access networks.

Structural Features:

- 2、4、6、8 and 12 fibres options.

- Stable structure, good mechanical, and temperature performance.

- Designed with special grooves to advance blowing distance.

- Lightweight and proper stiffness, repeat installation.

- Designed with no gel, easy stripping, and handling.

- Better costs advantage compared to traditional product.

- Complete accessories, less manpower, lower installation time.

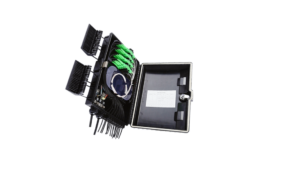

Super mini uni-tube air blown fiber cable structure

Structural Features:

• Special complex material loose tube, reduce the shrink of tube in cold temperature.

• Accurate fibre length balance, stable mechanical, and temperature performance.

• Particular technique control, prevent sheath form crinkling during installation.

• Structure Innovation in sheath, enhancing the blowing performance.

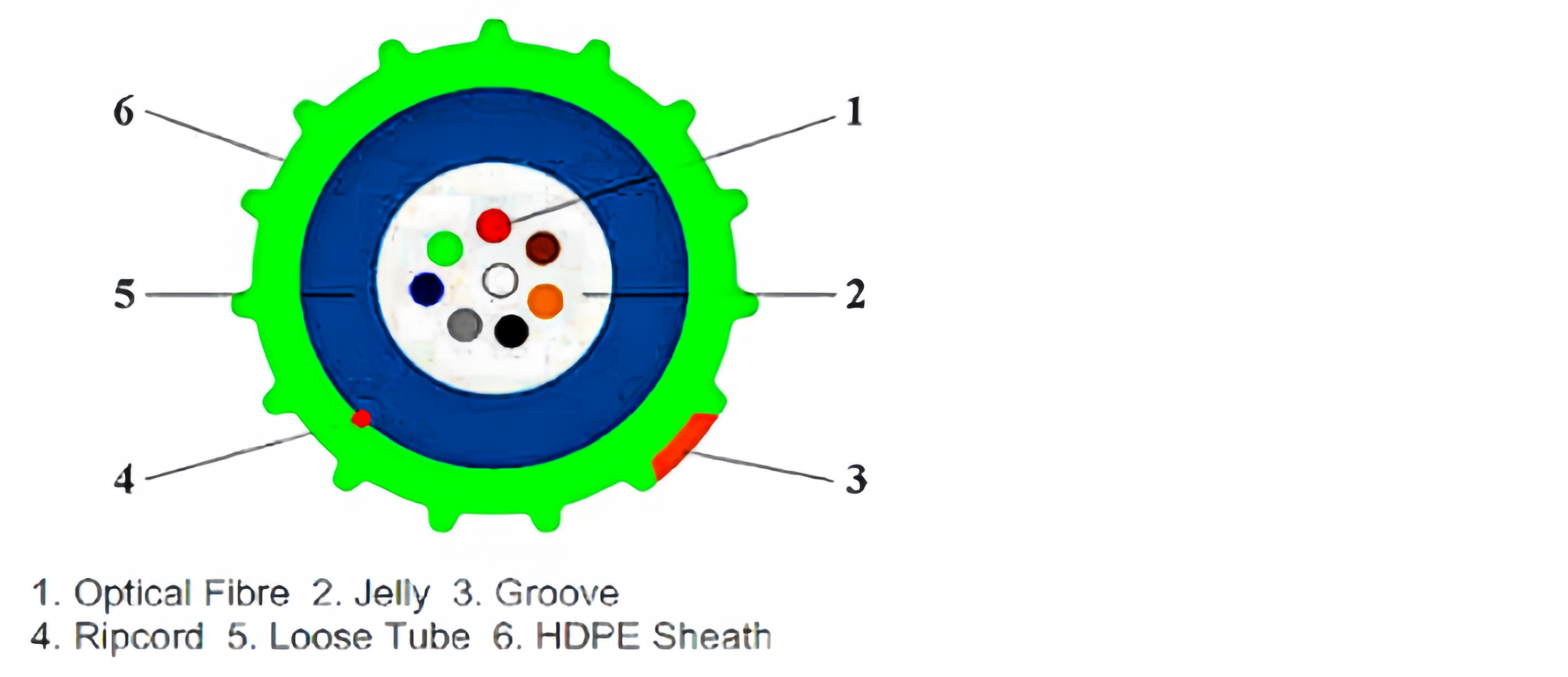

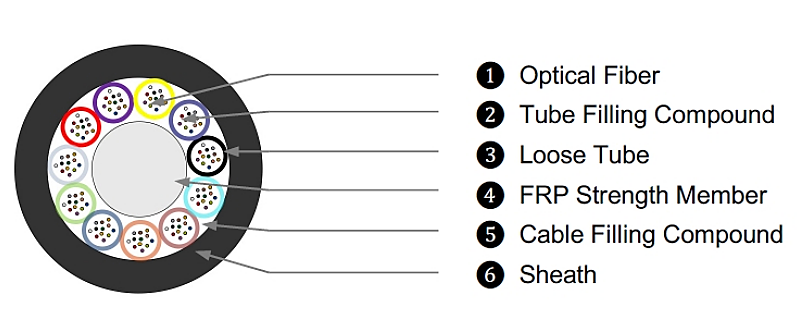

2–144 cores air blown cable structure

Structural Features:

- Optimum cable structure, high fibre density.

- Accurate fibre length balance, ensure stable performance.

- No gel in cable core for water blocking, low carbon and environmental.

- Structure Innovation in sheath, enhancing the blowing performance.

How to select the air blown fiber cable?

Distance of Cable Blowing

| Distance | Recommended Cable |

|---|---|

| Short (≤ 500 m) | EPFU – ultra-light, ideal for last drop to users |

| Medium (500 m – 1.5 km) | Super Mini Uni-tube – good balance of size and capacity |

| Long (≥ 1.5 km) | 24–144 Cores Air Blown Cable – optimized for long-distance backbone |

Fiber Count Requirements

| Fiber Demand | Recommended Cable |

|---|---|

| 1–12 cores | EPFU |

| 12–24 cores | Super Mini Uni-tube |

| 24–144 cores | 24–144 Cores Air Blown Cable |

Duct Size Compatibility

| Microduct Inner Diameter | Suitable Cable Type |

|---|---|

| 3–5 mm | EPFU |

| 5–8 mm | Super Mini Uni-tube |

| 10–14 mm | 24–144 Cores Air Blown Cable |

Application Scenario

| Scenario | Suggested Cable |

|---|---|

| FTTH last mile / final drop | EPFU |

| In-building / Floor distribution | Super Mini Uni-tube |

| Backbone / Metropolitan / Campus network | 24–144 Cores Air Blown Cable |

With different air blown fiber cable types available, selecting the right solution depends on blowing distance, fiber count, microduct size, and application scenario.

For a detailed selection guide, read How to Choose the Right Air Blown Fiber Cable

How does air blown fiber cable work?

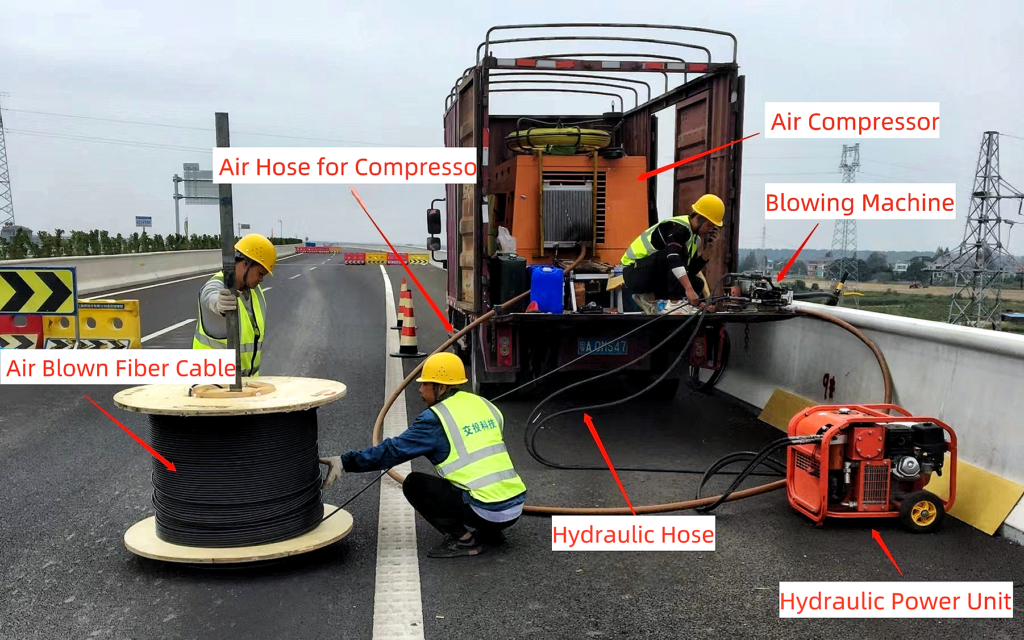

Air blown fiber is installed using a process that involves:

- Placing microducts in the ground, walls, ceilings, or existing conduits.

- Connecting blowing equipment at the entry point of the duct system.

- Blowing the fiber cable using air pressure or mechanical feeding.

- Monitoring cable movement to ensure safe delivery to the target location.

- Cables can typically be blown up to 1000–2000 meters in a single run, depending on duct quality, terrain, and cable structure.

Equipment Used for Air-Blown Fiber Optic Cable Installation

| Equipment Name | Description | Application Range |

|---|---|---|

| Duct Blowing Machine | Used for long-distance backbone projects to blow microducts into main ducts; also suitable for blowing fiber cables with an outer diameter over 14mm. | Microduct OD: 9–22mmMain duct OD: 20–60mm |

| Minijet 400 Blowing Machine | Suitable for blowing micro cables with 144 fibers or more into ducts. Ideal for high-capacity cable installation. | Cable diameter: 4–16mmDuct OD: 8–40mm |

| Small Air Compressor | Generates high-pressure air for micro cable installation. | Air flow: 0.8–1.2 m³/minPressure: 6–12 bar |

| Large Air Compressor | Provides high air volume and pressure for microduct installation, suitable for long-distance blowing. | Air flow: 10–15 m³/minPressure: 8–12 bar |

Advantages of air blown fiber cable

1. Scalable Deployment

With pre-laid ducts, fiber can be added only when needed — ideal for FTTH and future growth scenarios.

2. Cost Efficiency

No need to invest in all fibers during initial construction. Reduce CAPEX and align investment with actual customer activation.

3. Fast and Easy Installation

Blowing fiber through microducts is faster than pulling traditional cables. This reduces labor and time on site.

4. Minimal Disruption

No excavation or trenching is needed after duct installation — essential in cities, historical areas, or campuses.

5. Future-Proof Infrastructure

As data demands grow, new cables (higher fiber count, better performance) can be blown in without replacing the duct network.

6. Environmentally Friendly

Modular, reusable duct systems reduce material waste and environmental impact over time.

Applications of air blown fiber cable

FTTH (Fiber to the Home)、FTTB (Fiber to the Building)、FTTO (Fiber to the Office)

Campus Networks、Data Center Interconnections、Metro & Access Networks

Railway, Highway & Tunnel Communications、Military or Emergency Communication Systems

Its flexibility makes it ideal for both dense urban environments and remote rural networks where expansion happens gradually.

FAQs for air blown fiber cable

Q1: Can air blown cables be installed outdoors?

Yes. Our air blown cables are available with weather-resistant jackets suitable for direct burial, duct, or aerial applications.

Q2: What equipment is required to install air blown fiber?

You need a fiber blowing machine, air compressor, and duct connectors. Our team can recommend suitable tools or partners.

Q3: Are these cables compliant with international standards?

Yes. All our air blown cables are manufactured according to IEC, ITU-T, and ISO/IEC standards.

Q4: Can I upgrade to higher fiber counts in the future?

Absolutely. Simply blow in new cables through spare ducts without disrupting the existing network.

Conclusion of air blown fiber cable

Air blown fiber cable is more than just an installation method — it’s a future-ready strategy for building high-performance fiber optic networks. Whether you’re deploying FTTH in new developments or upgrading a city-wide backbone, our EPFU, Super Mini Uni-tube, and 24–288 Core Air Blown Cables offer flexible, scalable, and cost-effective solutions.