Indoor vs Outdoor Fiber Termination Boxes

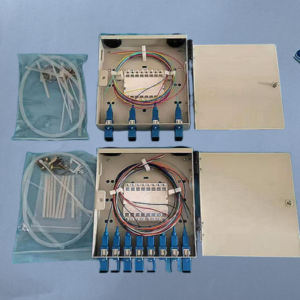

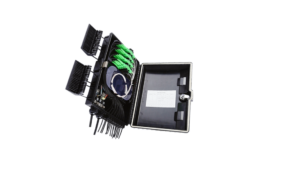

Introduction In fiber-to-the-home (FTTH) networks, fiber optic termination boxes are essential enclosures where cables are spliced, protected, and routed toward end users. Depending on where

Reliable outdoor fiber optic cables designed for tough conditions—fast, durable, customizable, and trusted by global network professionals.

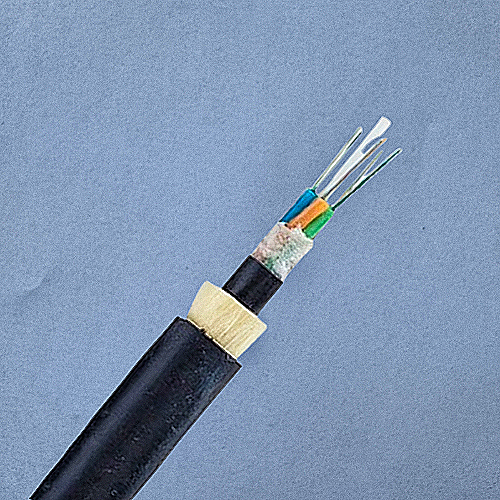

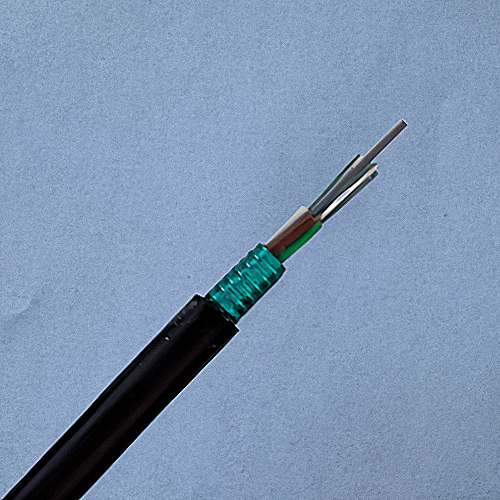

Self-supporting ADSS cable for aerial installation, with high tensile strength and weather resistance.

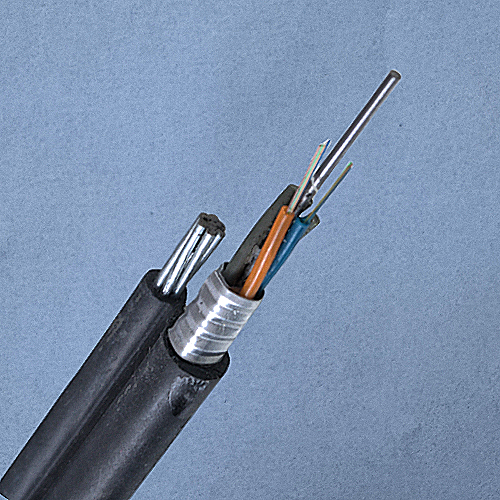

Figure 8 fiber cable with steel messenger, ideal for aerial installation with easy suspension.

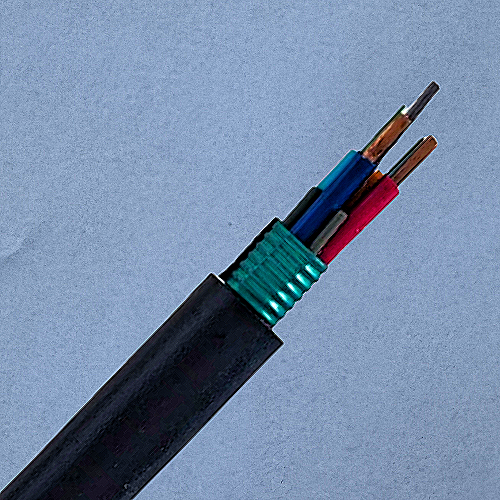

Hybrid outdoor cable combining fiber and power cores—ideal for FTTA and remote device connections.

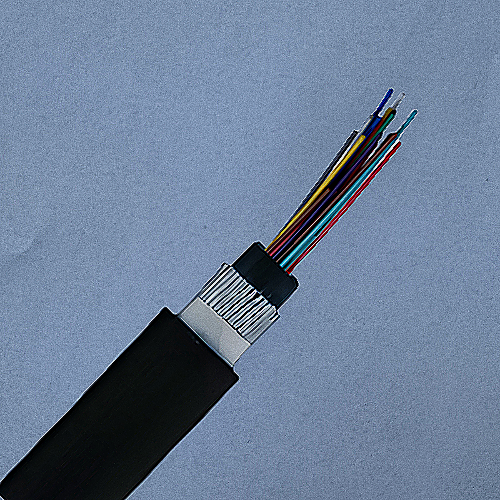

OPGW cable integrates fiber and ground wire—ideal for power lines with lightning protection.

Durable tight buffer cable with steel wire armor for indoor/outdoor use and strong mechanical protection.

Fiber optic cable with dual steel armor layers, ensuring superior crush resistance and durability

Lightweight outdoor fiber cable without armor, ideal for ducts and protected environments.

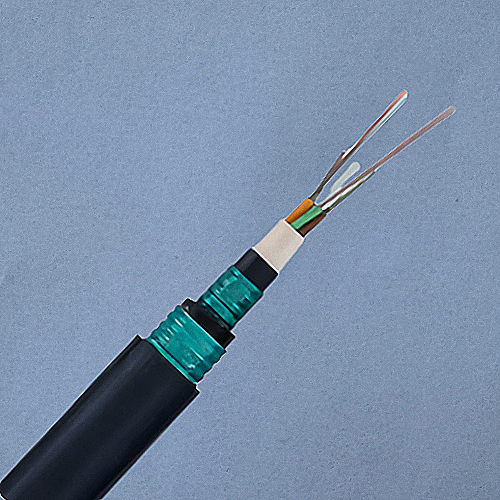

Outdoor fiber cable with corrugated steel tape armor for enhanced crush resistance and moisture protection.

From scorching deserts to frozen mountains, outdoor fiber optic cables are engineered to endure the elements — and deliver performance with precision. Wherever the signal must go, they lead the way

Outdoor fiber optic cables are designed to withstand harsh environmental conditions, and their performance largely depends on the materials used in their construction.

The outer jacket is typically made from polyethylene (PE), which offers excellent resistance to UV rays, moisture, and mechanical stress, making it ideal for direct burial or aerial installations.

In some applications, LSZH or TPU is used for added flame retardance or flexibility. Inside the cable, strength members such as fiber-reinforced plastic (FRP) or steel wire provide tensile strength and prevent damage during installation or operation.

To ensure water resistance, the cables often include water-blocking gels or swellable yarns that seal out moisture. Some outdoor cables are also armored with corrugated steel tape or aluminum to protect against rodents and physical impact.

These carefully selected materials ensure the cable maintains signal integrity and long-term reliability in challenging outdoor environments.

Suitable for aerial, direct-buried, underwater, and duct installations, outdoor fiber optic cables ensure reliable performance in harsh environments, offering strong protection against weather, moisture, mechanical stress, and physical damage.

.

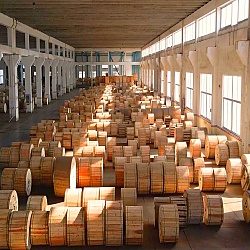

As your strategic partner, our fiber optic factory offering comprehensive solutions, expert guidance, and dedicated support throughout your project. From custom designs to on-time delivery, we are committed to helping you achieve success at every step.

![宏安集团 形象片 英文成片 20200103[00 00 27][20250527 181825111]](https://honelinks.com/wp-content/uploads/2025/06/宏安集团-形象片-英文成片-2020010300-00-2720250527-181825111-1024x576.jpg)

Successfully FTTH and Network Project Finished.

Serving clients around the world with customized solutions

Export and network industry experience with proud

Customer satisfaction is our top priority

“From customized fiber solutions to expert support, we deliver quality, speed, and reliability for every connection.”

Advanced production, strict quality control, and international certifications (ISO, CE, RoHS, UL).

Tailor-made fiber cables, OEM/ODM services, and diverse product options.

Factory-direct supply with cost-effective solutions and bulk discounts.

Efficient production, stable raw materials, and global logistics support.

“Customer satisfaction drives us forward. We are committed to quality, innovation, and exceptional service to exceed expectations.”

The fiber optic patch cord are top-notch, with excellent durability and low signal loss

Acme Inc.

The technical support team is very professional and responsive. I like this fiber optic factory

Aeser Corp.

Introduction In fiber-to-the-home (FTTH) networks, fiber optic termination boxes are essential enclosures where cables are spliced, protected, and routed toward end users. Depending on where

Introduction In Fiber-to-the-Home (FTTH) networks, optical splitters play a crucial role in dividing a single optical signal into multiple paths for distribution to end users.

Introduction In fiber-to-the-home (FTTH) deployments, the access network is designed to bring optical fiber as close as possible to the end user. Between backbone infrastructure

Introduction In FTTH access networks, multiple types of fiber enclosures are deployed at different stages of the optical path. Among them, fiber distribution boxes and

Introduction A fiber optic termination box is a core component in modern fiber optic networks, providing a secure and organized point for fiber termination, splicing,

Compare armored fiber optic cable prices from China manufacturers vs local suppliers. Learn cost differences, risks, and which option fits your project.

In today’s world, reliable internet connectivity is essential for both businesses and individuals. Outdoor fiber optic cables play a pivotal role in ensuring high-speed data transmission across networks, from rural broadband to city-wide fiber-optic deployments. These cables are specifically designed to withstand harsh environmental conditions, providing durability and optimal performance even in the toughest climates.

Whether you’re installing fiber optics in a remote area, connecting urban centers, or setting up a long-distance network, this comprehensive guide will help you understand the different types of outdoor fiber optic cables, their benefits, and how to install and maintain them for a high-performing network.

Outdoor fiber optic cables are designed for use in outdoor environments, where they must withstand environmental factors like moisture, UV rays, temperature extremes, and physical damage. Unlike indoor cables, which are typically lighter and more flexible, outdoor cables are made with durable materials and protective coatings to ensure they remain operational under challenging conditions.

The key advantage of fiber optic cables lies in their ability to transmit large amounts of data over long distances with minimal signal loss, making them perfect for communication systems, broadband, and data centers.

| Cable Type | Structure | Typical Use |

|---|---|---|

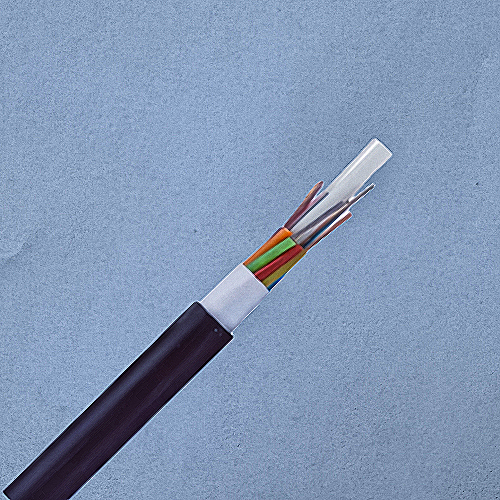

| Loose Tube Cable | Central loose tube, gel-filled | Underground, long-haul |

| Armored Cable | Steel tape or corrugated steel | Harsh environments, direct-buried |

| Figure-8 Cable | Self-supporting with steel wire | Aerial installations |

| Air Blown Cable | Microduct, lightweight | Flexible, future expansion |

| ADSS Cable | All-Dielectric, Self-Supporting | Aerial over power lines |

Browse Our Range of Outdoor Fiber Optic Cables

There are several types of outdoor fiber optic cables, each suited for specific environmental conditions and installation requirements. Let’s dive into the main options available:

ADSS fiber optic cables are used for overhead installations and are ideal for areas where there’s no metallic infrastructure. The “all-dielectric” feature means the cable doesn’t require metal elements for support, making it highly resistant to electrical interference. ADSS cables are often used for long-distance connections between cities or to provide broadband in rural areas.

Best for: Long-distance aerial installations and rural broadband.

Learn more about ADSS Fiber Optic Cables and their applications.

Armored fiber optic cables have a protective armor layer made of steel or aluminum to prevent damage from physical impacts such as digging or rodent interference. These cables are highly durable and ideal for underground installations, making them perfect for areas prone to physical damage.

Best for: Underground and direct burial installations.

Explore the benefits of Armored Fiber Optic Cables for underground use.

Gel-filled fiber optic cables are designed for environments where moisture is a concern. The gel inside the cable prevents water from entering and affecting the fibers, ensuring signal integrity. These cables are typically used in areas with high humidity or underwater applications.

Best for: Moisture-rich environments and underwater applications.

Find out how gel-filled cables protect against moisture.

Loose tube fiber optic cables feature a flexible design where the optical fibers are housed inside a tube that can expand and contract as needed. This design makes loose tube cables perfect for areas with extreme temperature fluctuations, as they can handle thermal expansion without damaging the fibers.

Best for: Areas with temperature extremes.

Learn more about Loose Tube Fiber Optic Cables.

Outdoor fiber optic cables offer several key advantages that make them an ideal choice for building high-speed, reliable networks:

Outdoor fiber optic cables can transmit data at incredibly high speeds, much faster than copper cables. This speed allows for smoother, faster communication, whether you’re streaming videos, running cloud applications, or supporting critical infrastructure.

These cables are built to withstand the toughest outdoor conditions. They are resistant to UV rays, rain, moisture, and extreme temperatures, ensuring they remain operational year-round.

Fiber optic cables have a much lower latency compared to traditional cables. This means data is transmitted almost instantly, which is essential for real-time applications like video conferencing, live streaming, and remote work.

Once installed, outdoor fiber optic cables require minimal maintenance. They have a long lifespan, typically 20-30 years, making them a cost-effective choice for long-term infrastructure projects.

Installing outdoor fiber optic cables requires careful planning to ensure they perform optimally over their lifespan. Here’s a general overview of the installation process:

Planning is critical for a successful installation. You’ll need to determine the best path for the fiber optic cables, avoiding obstacles such as power lines, roads, or potential construction sites. Be sure to account for the necessary physical protection in areas prone to damage.

For underground installations, trenches need to be dug to lay the cables safely. Make sure the depth of the trench is adequate to prevent damage from external forces. A protective conduit may be needed in certain environments.

Fiber optic cables are delicate and can easily be damaged by excessive tension or sharp bends. During installation, make sure to follow the manufacturer’s specifications for handling the cables to avoid damaging them.

Use conduits or other protective materials to shield the cables from physical damage, particularly in areas with heavy foot traffic or potential construction zones.

While fiber optic cables require minimal maintenance, it’s important to conduct regular inspections to ensure that they are functioning properly. Here are some tips for maintaining your outdoor fiber optic network:

Check the cables for any signs of damage, such as cuts, abrasions, or water infiltration. If you notice any issues, address them immediately to prevent signal loss.

Dirt or debris on the fiber optic connectors can affect performance. Regularly clean the connectors using fiber optic cleaning tools to ensure optimal signal quality.

Use fiber optic testing equipment to check the signal strength and overall performance of the network. This will help you detect any issues before they become significant problems.

If you detect any issues with signal quality, such as loss of data or slow speeds, address them immediately to avoid network downtime.

Check out our guide on maintaining outdoor fiber optic networks here.

Outdoor fiber optic cables are a vital part of modern network infrastructure, providing high-speed, reliable, and long-lasting communication solutions. Whether you’re setting up a new network or upgrading an existing one, choosing the right outdoor fiber optic cable is crucial to ensure that your network performs at its best.

By understanding the types of cables available, their benefits, and how to install and maintain them, you can make informed decisions that will improve the performance of your network. To learn more about our outdoor fiber optic solutions, explore our full range of products here.

Outdoor cables are designed to withstand harsh environmental conditions such as UV radiation, moisture, temperature extremes, and mechanical stress. They typically feature water-blocking elements, UV-resistant jackets, and stronger armoring compared to indoor cables.

Yes. Direct-buried outdoor fiber cables are specifically built with armored layers and water-blocking materials to resist soil pressure, rodent attacks, and moisture, making them ideal for underground networks.

Common jacket materials include LSZH (Low Smoke Zero Halogen) and TPU (Thermoplastic Polyurethane). These provide UV resistance, flexibility, and fire safety, depending on the application environment.

Yes. For pole-to-pole or aerial deployment, self-supporting cables like ADSS (All-Dielectric Self-Supporting) are widely used. They are lightweight, corrosion-resistant, and easy to install without messenger wir

It depends on your installation method (aerial, duct, direct burial, underwater), environmental conditions, fiber count, and budget. Consulting with a technical expert is recommended to select the best-fit structure.

Yes. Most outdoor fiber cables include water-blocking gel, yarn, or tape to prevent moisture ingress. Some are fully waterproof and can even be used in submerged or flood-prone areas.

Contact our factory today! With 23 years of experience in fiber optic manufacturing, we are committed to providing you with the most suitable solutions for FTTH projects, fiber optic networks, and customized needs. Choosing us means high-quality products, professional support, and cost-effective solutions. Don’t wait—take action now and reach out to us to make your project more efficient and successful!

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!

REPLY WITHIN 24 HOURS

Leave your inquiry here

will respond with technical support and pricing within 24 hours.