Get Started Today!

EXPLORE OUR FIBER OPTIC AND FTTH SOLUTIONS FIND THE ONE THAT WORKS BEST FOR YOU.

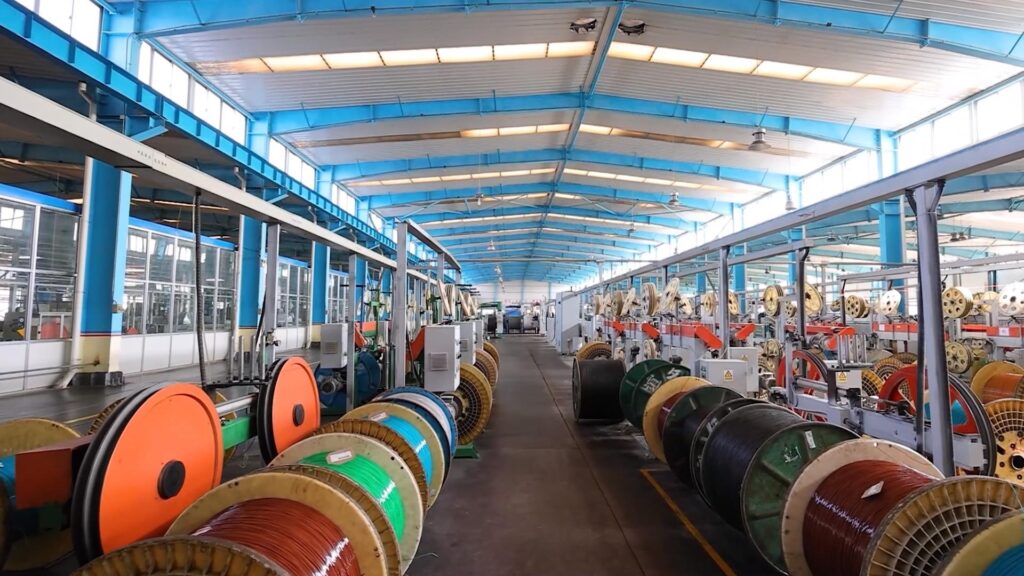

Contact our factory today! With 23 years of experience in fiber optic manufacturing, we are committed to providing you with the most suitable solutions for FTTH projects, fiber optic networks, and customized needs. Choosing us means high-quality products, professional support, and cost-effective solutions. Don’t wait—take action now and reach out to us to make your project more efficient and successful!

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!

Ask For Quote Now!

REPLY WITHIN 24 HOURS