AT Jacket vs PE Jacket ADSS Cable Price: Which One better?

Compare AT jacket vs PE jacket ADSS cable price, performance, and application. Learn which jacket type is suitable for high-voltage and standard aerial fiber projects.

Guides, tutorials, case studies, and more to help you make informed decisions.

Compare AT jacket vs PE jacket ADSS cable price, performance, and application. Learn which jacket type is suitable for high-voltage and standard aerial fiber projects.

What Are Gel-Filled Fiber Optic Cables? Gel-filled fiber optic cables are a type of fiber optic cable designed for environments where moisture and water are

Why Is Proper Installation Crucial for Outdoor Fiber Optic Cables? The installation of outdoor fiber optic cables is a critical step in ensuring the long-term

What Are Armored Fiber Optic Cables? Armored fiber optic cables are specially designed to provide an additional layer of protection against external factors that could

What is ADSS Fiber Optic Cable? ADSS (All-Dielectric Self-Supporting) fiber optic cables are designed for overhead applications, offering the ideal solution for long-distance communication in

Installing a fiber optic patch panel may seem straightforward, but many network issues originate from small installation mistakes. Poor fiber routing, incorrect bend radius, or

We are a factory with over 20 years of experience in the fiber optic industry. Every cable we produce and every connector we assemble reflects our commitment to quality and reliability. We understand that every detail matters in a network project — that’s why we’re not just manufacturers, but also your technical support team.

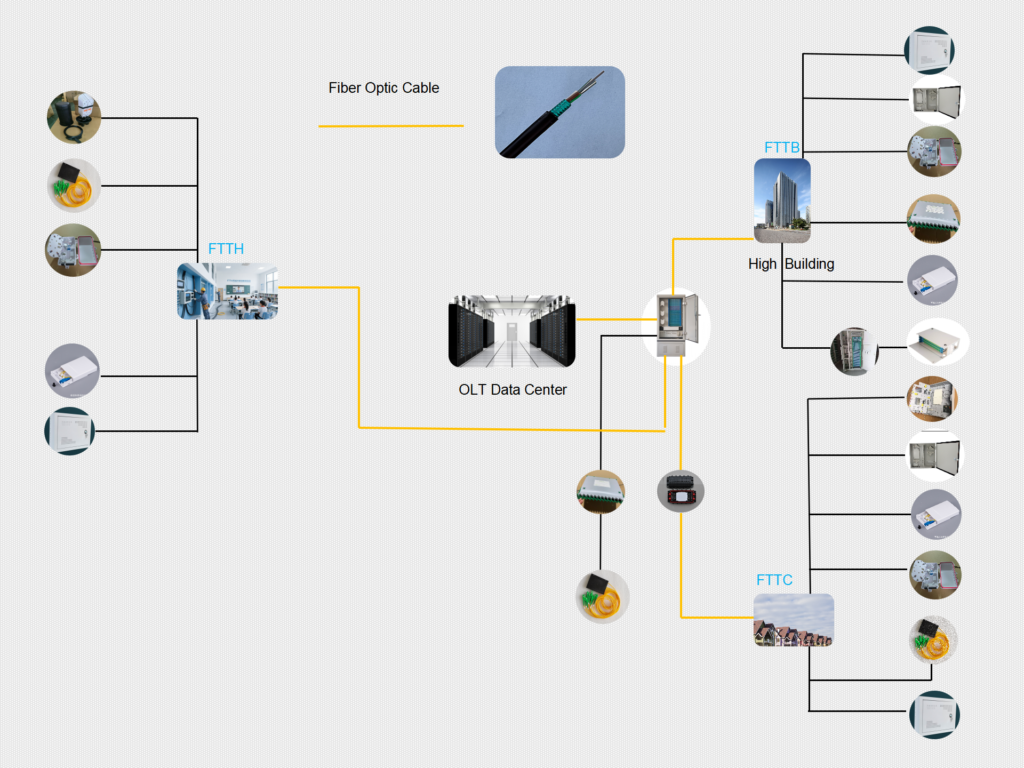

Whether you’re planning an FTTH deployment or looking for the right solution for your network, we’re here to help. Our engineers are ready to answer your questions and offer expert guidance.

Let’s start with a conversation. Contact us today — we’re just one message away.

Our downloadable guides and eBooks offer practical insights and technical support for fiber optic systems. Whether you’re planning an FTTH project or need installation tips, these resources are made to assist engineers, managers, and buyers.

From product manuals to deployment guides, we provide key documents in one place. All files are free to download and regularly updated by our technical team to reflect the latest in fiber optic technology..

Answer

Signal loss (attenuation) is often caused by connector contamination, excessive bending, poor splicing, or damaged fibers.

Detailed Explanation

Signal loss in fiber optics reduces transmission efficiency. Common causes include dirty connectors, sharp bends beyond minimum bend radius, poor splicing quality, micro-cracks, or improper cable installation.

Troubleshooting Steps

Clean all connectors with fiber-grade tools

Use an OTDR to locate loss points

Check bend radius and straighten any tight curves

Re-splice if fusion loss exceeds threshold

Inspect for physical damage or crush points

Answer

Improper duct sealing, overblowing speed, and using wrong cable type can cause failures during installation.

Detailed Explanation

Air blown fiber systems rely on controlled air pressure and duct integrity. Mistakes like using wet ducts, overloading the cable path, or mismatched cable/duct diameter reduce efficiency or cause blockages.

Troubleshooting Steps

Always clean and dry microducts before installation

Match cable diameter to duct specification

Use correct blowing machine settings (speed/pressure)

Avoid sharp bends and crushed ducts

Monitor cable distance and friction during blowing

Answer

Fusion splicers display error codes for issues like poor cleaving, dirty lenses, misaligned fibers, or arc problems.

Detailed Explanation

Each model has specific error codes. For example, “LENS DUST ERROR” means the internal camera lens needs cleaning. Others indicate arc calibration failure, fiber detection error, or cleave angle too large.

Troubleshooting Steps

Clean V-grooves and mirrors with isopropyl alcohol

Re-cleave fiber ends if cleave angle is poor

Perform arc calibration before splicing

Refer to user manual for specific error code meanings

Ensure correct fiber type is selected (SM/MM)

Answer

Use dry or wet cleaning methods with specialized fiber cleaning tools to avoid contamination-related signal loss.

Detailed Explanation

Dirty connectors are the top cause of insertion loss. Even microscopic dust can disrupt light transmission. Use lint-free wipes, isopropyl alcohol, or reel-based cleaners.

Troubleshooting Steps

Inspect connector under fiber microscope (200x–400x)

If dirty, use dry cleaning first (e.g., pen cleaner)

If still dirty, apply wet-dry cleaning: alcohol then dry wipe

Reinspect after cleaning to confirm cleanliness

Answer

Check for loose connections, incorrect polarity, fiber breaks, or dirt in the connectors.

Detailed Explanation

FTTH drop cables are thin and prone to damage. Installation errors, poor handling, or improper termination often lead to no signal or high attenuation.

Troubleshooting Steps

Confirm proper connector insertion

Check polarity (A/B match)

Test cable with VFL or OTDR

Replace damaged connectors

Avoid sharp bends or excessive tension on drop cable

Answer

Use an Optical Power Meter and Light Source or an OTDR to validate fiber link quality.

Detailed Explanation

Testing ensures the fiber link meets expected loss and continuity standards. Each method provides different levels of detail: power meters measure end-to-end loss; OTDR locates events like splices or breaks.

Troubleshooting Steps

Perform visual inspection first

Use power meter and light source for insertion loss test

Use OTDR to detect splices, breaks, and loss points

Compare results to system requirements or budget

Document test results for certification

Answer

Extreme temperatures, UV, moisture, and mechanical stress can degrade fiber optic performance.

Detailed Explanation

Outdoor and harsh environments pose risks to fiber cables. Jacket degradation, water ingress, and expansion/contraction affect signal integrity and long-term durability.

Troubleshooting Steps

Use cables rated for the environment (e.g., LSZH, TPU, armored)

Ensure proper sealing at closures and entry points

Avoid over-tension and tight bends during installation

Inspect regularly in high-risk areas (e.g., rooftops, ducts)

Replace aged or UV-damaged cable sections

Answer

Store fiber cables in dry, shaded areas and handle with care to prevent microbending and jacket damage.

Detailed Explanation

Fiber is fragile and must be coiled, lifted, and stored with proper techniques. Kinks, crushing, or dragging can cause hidden damage before installation.

Troubleshooting Steps

Store reels upright on flat surfaces

Avoid stacking heavy items on fiber reels

Use lifting rings or handles—not the cable itself

Respect minimum bend radius at all times

Cover ends to keep out dust and moisture

Contact our factory today! With 23 years of experience in fiber optic manufacturing, we are committed to providing you with the most suitable solutions for FTTH projects, fiber optic networks, and customized needs. Choosing us means high-quality products, professional support, and cost-effective solutions. Don’t wait—take action now and reach out to us to make your project more efficient and successful!

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!

REPLY WITHIN 24 HOURS

Leave your inquiry here

will respond with technical support and pricing within 24 hours.